The piling machine manufacturer relies on Teknikum’s quality and know-how in rubber parts

“From a designer’s point of view, cooperation with Teknikum is easy and functional when you don’t have to try to be a specialist in the rubber industry yourself,” says Junttan Oy’s senior design engineer Tatu Silvast.

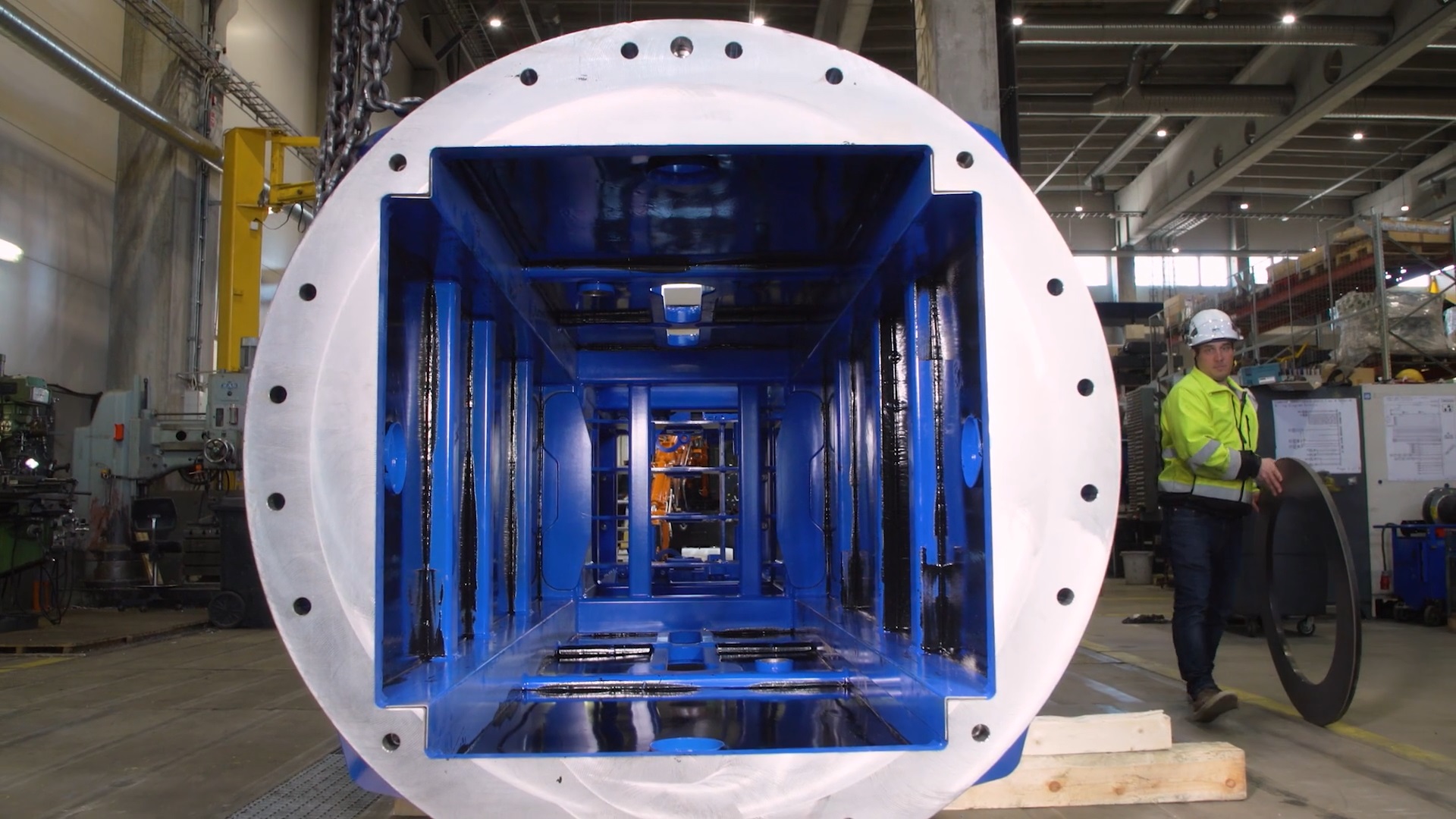

A hammer – more than a fitting name for a part of a machine with total mass of almost 70 tons and and the mass of the striking part 28 tons, in the model presented by mechanical designer Tatu Silvast.

We are at Junttan Oy‘s premises in Kuopio, from where the world’s leading manufacturer of hydraulic piling equipment delivers its products to many countries and continents.

“Most of our machines are exported, but every year a few of them also stay here in Finland,” says Silvast.

The rubber compound manufactured by Teknikum guarantees the functionality and long service life of the hammers used for piling foundations.

Each construction project has its own special features, and the soil affects how piling is best implemented. Knowing the methods, Junttan Oy designs and manufactures hydraulic piling equipment, and its product range includes pile driving rigs, multi-purpose and drilling rigs, as well as hydraulic hammers, rotary heads and power packs.

When huge masses and forces are in motion, damping ability is also needed, and then, according to Silvast, high-quality bouncing rubber is key.

From a designer’s point of view, cooperation with Teknikum is easy and functional, when you don’t have to try to be a specialist in the rubber industry yourself. It’s enough to tell Teknikum the features required of the product, and after that I can trust that we will get a good product from them for our use”, praises Tatu Silvast.

This quality part ensures stable blows and a long service life of the hammer.

“The bouncing rubber acts as an insulator by separating the hammer from the pile and the hitting event. There must be damping ability, but the bouncing rubber must not be too elastic, so that it does not start jumping up the hammer’s frame,” explains Silvast.

In pile driving, a pile made of concrete, steel or wood is raised and installed in the ground by hitting the top end of the pile with a hydraulic hammer. In this case, the tip of the pile displaces the soil around the pile. Pile driving is known as both a cost-effective and environmentally friendly method, because the work progresses quickly without the need to remove soil material. There is almost no need for other work machines either.

“The bouncing rubber plays a really significant role in the structure of the hammer: without it, the hammer’s lifespan would be much shorter and the hitting event much more unstable.”

In the largest Teknikum compression molding machines, the pressing force reaches thousands of tons, and the machine base enables molds and customized end-products up to several meters in size.

Teknikum serves many major European machine builders. The company manufactures customer-specific products from rubber, plastic, silicone, polyurethane and technical foam in its factories located in Finland and Hungary.

In the largest compression molding machines, the pressing force reaches thousands of tons, and the machine base enables the molds even in the size range of several meters. Such products are needed not only in large work machines but also in demanding industrial processes and urban infrastructure.

Recently, Teknikum has delivered e.g. rubber plate bearings for the vibration isolation of TYKS Lighthouse Hospital and rubber level crossing elements for Tampere city’s new tramway.

Products like this can be reinforced with nylon or metal plates, in addition to the development of a suitable rubber compound. Teknikum’s product development department is experienced in combining different raw materials in a consistent and lasting manner as well as developing solution according to special requirements. The product developed for Junttan was designed in close cooperation with the customer.

As an expert in his own field, Silvast places high value on a partner offering the special expertise in the rubber industry.

“From a designer’s point of view, cooperation with Teknikum is easy and functional when you don’t have to try to be a specialist in the rubber industry yourself. It’s enough to tell Teknikum the features required of the product, and after that I can trust that we will get a good product from them for our use”, praises Tatu Silvast.

In impact piling, a pile made of concrete, steel or wood is raised and installed in the ground by hitting the top end of the pile with a hydraulic hammer.

“We have been able to develop such a cost-effective solution with Teknikum that it is always worth keeping these in stock,” says Silvast.

Teknikum knows the needs of machine builders and demanding operating environments. Experience has been accumulated for decades, from parts of work machines to parts of the mining industry, respirators of the national defense and material transfer hoses of power plants. At the company’s core of competence is material development and knowledge.

“Teknikum is a comprehensive supplier for the needs of industrial customers. We provide everything from raw material development to prototypes and final product manufacturing. The supply chain is safe for the customer because it is completely under our control from start to finish,” says Riku Sivula, Teknikum’s Director, Moulded products and Lining BU.

In 2022, Teknikum was one of the first polymer industrial companies to commit to the Paris Climate Agreement and to reducing emissions with the Science Based Targets initiative. Taking environmental impacts into account is part of the company’s strategy to ensure sustainable solutions for customers now and in the future. A competitive advantage is also produced by agile service and product development support offered to the customers. When it comes to securing a supply chain, the safe European operator Teknikum is a reliable and cost-effective choice for any machine builder.

Contact for more information

Industrial customers, Moulded products

Satu Hyökki-Siltanen

Sales Manager, Moulded products BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 468 1181

Martti Jokela

Director, New Business Development

Teknikum Group Ltd, Central Europe

firstname.lastname@teknikum.com

+358 50 306 2172

Riku Sivula

Director, Moulded products & Linings Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 445 2255Ota yhteyttä

Teknicross® products

Jukka Pausola

Product and Sales Manager, Moulded products BU

firstname.lastname@teknikum.com

+358456399354Industrial customers, Moulded products

Satu Hyökki-Siltanen

Sales Manager, Moulded products BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 468 1181

Riku Sivula

Director, Moulded products & Linings Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 445 2255