Matti Pohjala

Sales Manager, Linings BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

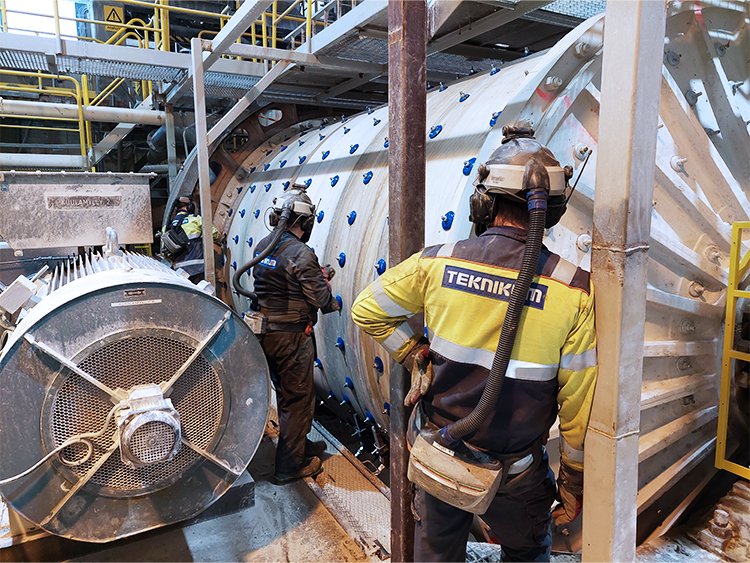

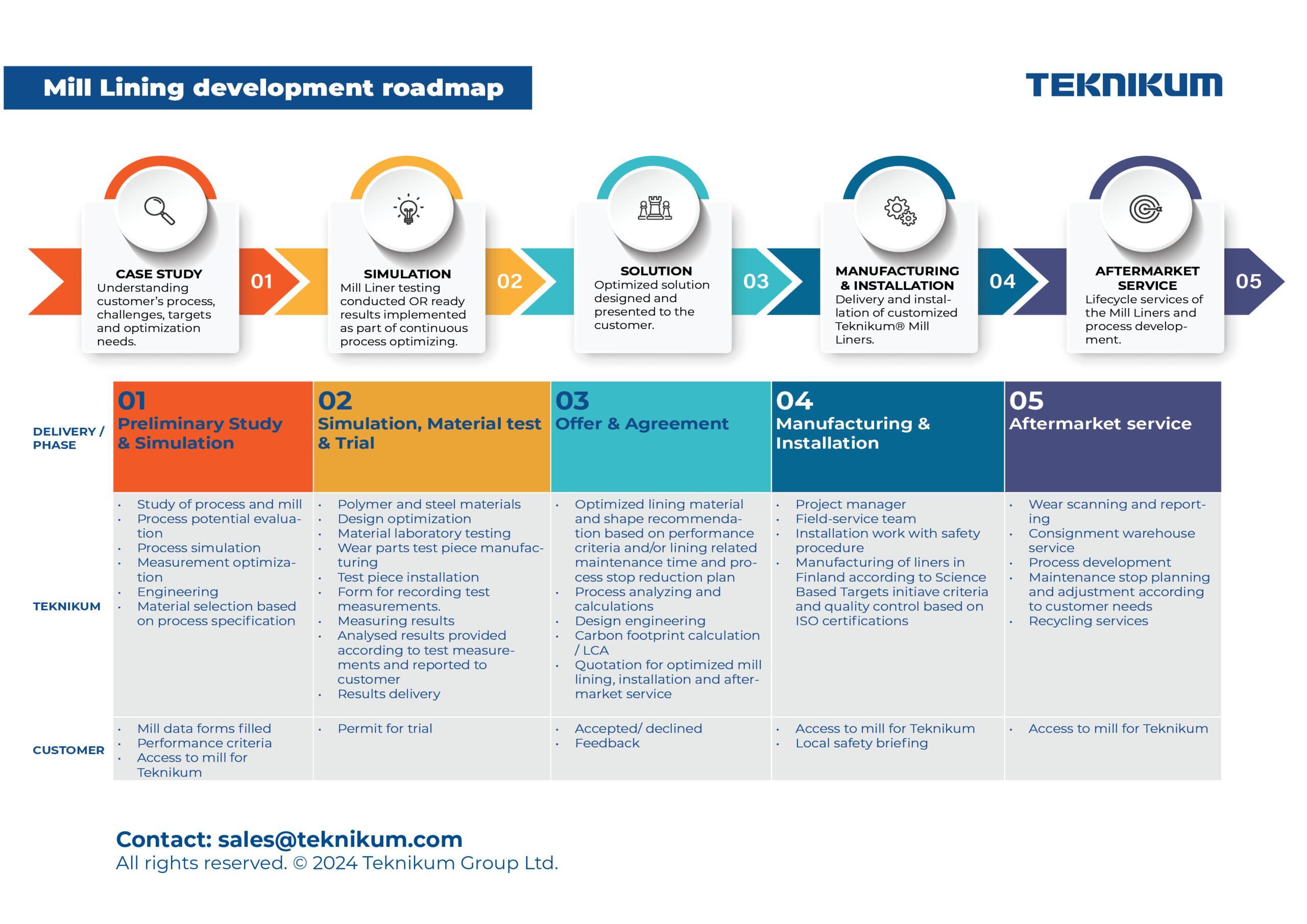

+358 50 329 9948Teknikum designs and manufacturers grinding mill linings. Our specialty is optimizing the lining according to customer expectations.

In addition to lining, our services include manufacturing lining components with different reinforcements and latest fixing methods as well as mill lining installation services incl. supervision, high-quality measurement and lifetime estimation technologies.

Lining design and rubber grade selection is done specifically to the process and in close cooperation with the customer.

We aim for the optimal in-service lifetime and optimal grinding media results.

Via process simulation we can tackle even the most challenging technical issues related to grinding.

Our own laboratory and product development unit guarantees continuous material development and testing.c

We are dedicated to optimizing the customer’s grinding result and offer our 30 years of expertise in this special field. Our passion is to optimize and forecast life time of each mill lining for predictable material flow.

Rubber, Polyurethane or Steel Top – We provide liners for mill types:

Flexible customer-oriented service is our ambition. We serve several Mining Industry customers continuously on-site, project based or with long-term contract, depending on need.

Products made of Teknikum Pucast® polyurethane are used in the processing and mining industries and demanding special applications, where resistance to wear, load-bearing capacity or soundproofing is needed.

Our manufacturing technique is suitable for both small and large production series, and we offer vast product development experience and technical support. We have modern, computer-aided design and simulation systems. Our products are designed in collaboration with our customers.

Teknikum® TRL rubber grades are especially developed for the use in the mining industry with over 30 years of expertise.

Our material offering covers various rubber grades with specific resilience.

We conduct the practical tests together with your team in the actual usage environment, to develop and select the best lining solution for your Mill.

Optimize your mill operation and service functions with us – get the full benefit of our services and know-how. Sustainably.

Contact our sales for more information!

Matti Pohjala

Sales Manager, Linings BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 329 9948

Riku Sivula

Director, Moulded products & Linings Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 445 2255Mill Lining Services

Samu Grönroos

Sales Manager, Linings BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 337 5843

We are committed to the Science Based Targets initiative (SBTi) to reduce emissions according to Paris Agreement and Finnish chemical industry’s Responsible Care –environmental programme that is the most long-running and renowned voluntary programme supporting sustainable development.

We take into account the environmental effects in everything we do – by setting goals that make our operations even more environmentally friendly. The safety of environment, our customers and employees is our top priority.