Polyurethane – for extra wear-resistance

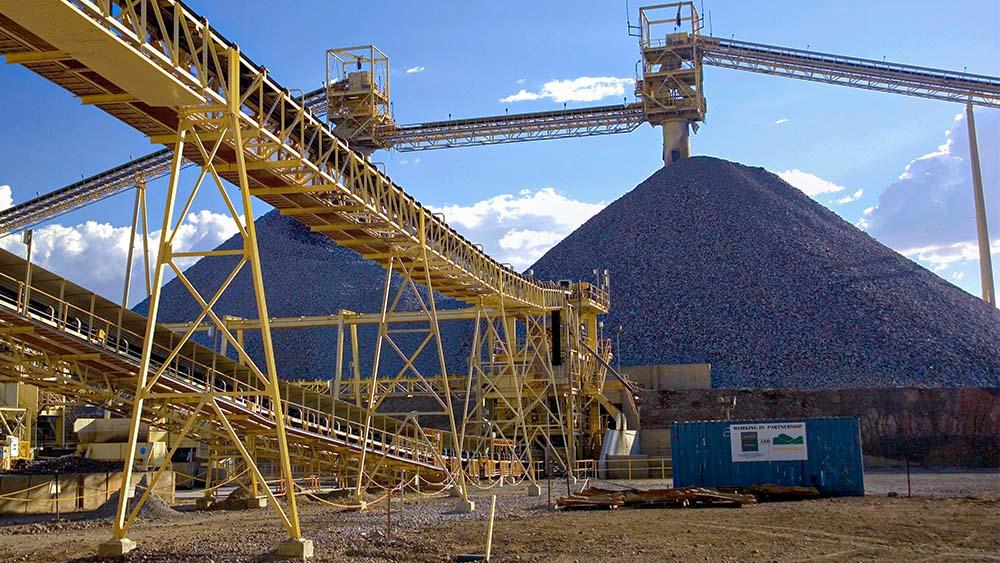

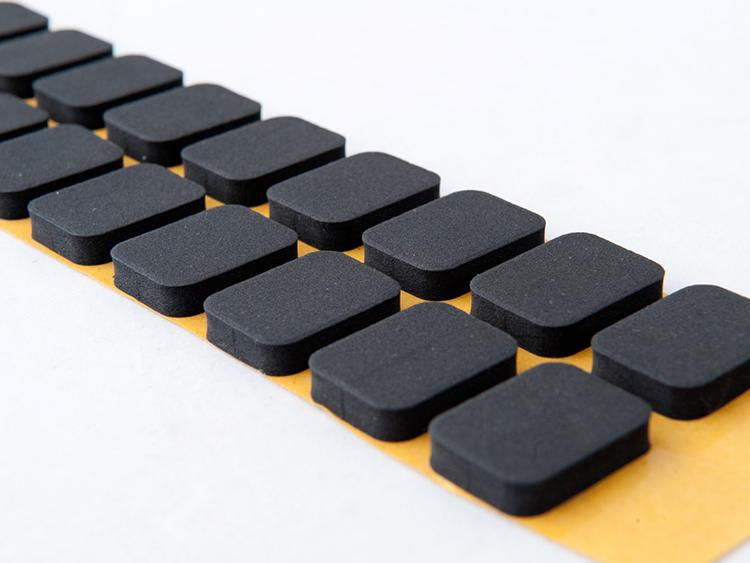

Products made of Teknikum Pucast® polyurethane are used all over the world, for instance in the processing and mining industries, mechanical wood processing equipment, and demanding special applications, where resistance to wear, load-bearing capacity or soundproofing is needed.

As material, Teknikum Pucast® polyurethane provides easy processability. The products can be made completely of polyurethane or equipped with metal frames.

Our manufacturing technique is suitable for both small and large production series, and we offer vast product development experience and technical support. We have modern, computer-aided design and simulation systems. Our products are designed in collaboration with our customers.

NYRIM® is a polyamide-based material that gives products a combination of the hardness, rigidity, and chemical and thermal resistance of polyamide and the elasticity and viscosity of rubber. NYRIM® introduces durability and lightness to solutions that utilise it, and fillers enable modifying the properties of the products. Reaction injection moulding (RIM) enables large product volumes and low moulding costs.

Teknikum offers specific manufacturing capabilities for NYRIM® based product manufacturing.

Read more

Plastic

Using the ejecting press and extrusion techniques, our Plastic BU manufactures customer-specific special products and hoses. The unit’s raw materials selection covers all the main grades of basic plastics, thermoplastic elastomers, and certain technical plastics such as POM, PA, and PA + fiberglass compounds.

Some of our products may be very small in size, but our equipment also enables making very large plastic products with up to 2,000 cubic centimetres in volume.

Sustainable materials

We can utilize recycled polymer raw-materials in the production, as the material specification is based on customer requirements.

With our own products, recycled rubber is used e.g. Teknikum® Heavy duty cable protector.

Our high degree of automation and the recyclability of materials guarantee an environmentally-friendly manufacturing process.

Read more