May 6, 2024 – Sastamala, Finland

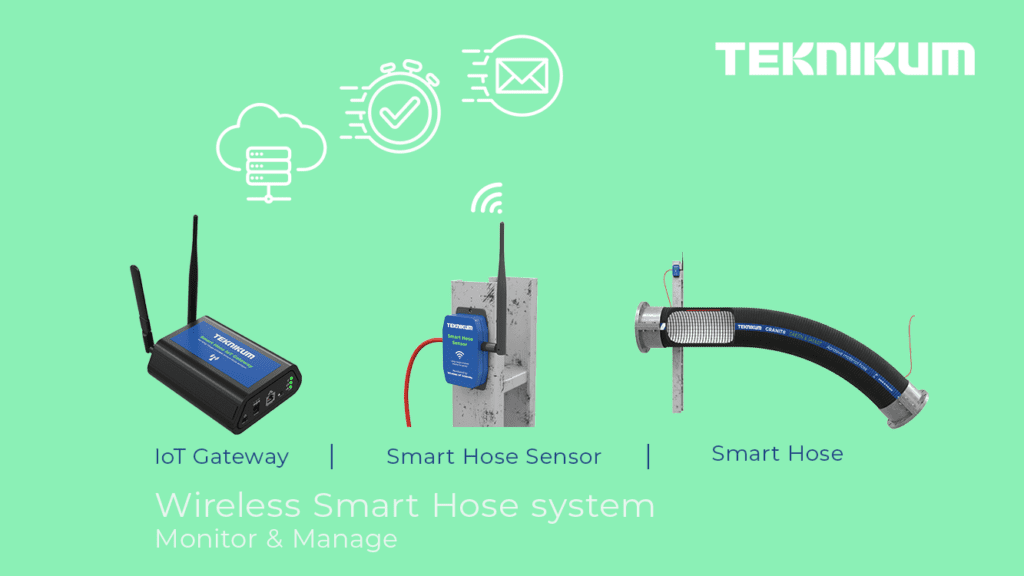

In spring 2024, Teknikum brings forth an upgraded wireless solution for wear monitoring of abrasive smart hoses. To enable even more maintenance cost savings and as easy lifecycle management as possible, the system is now built around a Wireless IoT Gateway that is able to monitor up to 20 smart hoses at once. When multiple IoT Gateways are installed, the coverage can include hundreds of hoses and bends.

Customer’s piloting the system have been very pleased to receive feedback on their hoses durability without the need to make a maintenance stop and a visual check. But how is it done today?

When a Smart hose’s lining reaches a specific point of wear, the Wireless Smart hose sensor sends an alert to the IoT Gateway, and all the way to Teknikum’s secure Cloud-based monitoring system. The alert point is within the rubber lining layers and by calculating the use life to the point of alert, it’s possible to estimate exact life of the hose until the point of wearing out.

The alert point gives typically more reaction time with rubber hoses, but with CERAMIC lining and highly abrasive materials, the reaction time can be few days – and thus the information is critical. Teknikum’s CERAMIC lining itself allows 3-10 times longer life than a rubber hose or a steel pipe. When this long life solutions is combined with the Wireless Smart Hose system, industrial plants in Mining and Energy sector can operate on high performance risk-free.

“We are very excited to launch this new system and believe that it will solve critical operational issues and make plant management easier for our customers”, says Mr. Timo Kokkonen, Director of Teknikum Hoses BU.

We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach.

A significant part of the added value is the continuous development of materials in-house.

– Timo Kokkonen, Director, Hoses BU

Bringing added value to various harsh operational environments

This new wireless monitoring system is especially designed for environments, where abrasive hoses are used. This includes Energy, Mining and other heavy industries. Some examples of the use cases are transfer of sand, rocks, minerals and granulates.

The most critical place for the abrasive material handling is an outer curve of a hose. Teknikum’s new Smart Hose monitoring solution offers various technical structures for it: according to customers’ needs, the monitoring cable can be built within one or two rubber layers and distributed even to various sectors. This allows the process owner to manage efficiently over the hoses’ life cycle – in some cases straight hoses it can be even turned 3 times during their use, to get most out of the inner lining.

Secure cloud-based monitoring enables fast off-site alerts and advanced material development

In the core of Teknikum’s IoT solution is its new cloud-based monitoring software. When data is received from site via the sensors and IoT Gateway, it’s processed withing the monitoring system. The alert points are defined together with the customer and when triggered, the system sends an alert to the customer. In addition, the system collects important wear monitoring data from the hose’s lining that allows continuous in-house material and product development for the customer’s operation environment.

“We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach. A significant part of the added value is the continuous development of materials in-house”, says Mr. Kokkonen.

» Teknikum is launching the new system at EuroMine expo, Skellefteå, SWEDEN 28 – 30 May 2024. Visit our team at booth #208 in Copper Hall and check out our Wireless Smart Hose system demo!

Contact us to learn more

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263Heavy process industry and mining industry

Jani Lampinen

Sales Manager, Industrial hoses BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 411 7810March 19, 2024 – Finland

Teknikum, a Finnish polymer technology company and pioneer in sustainable solutions, committed to Science Based Targets initiative in 2021. In May 2023, the SBTi organization approved Teknikum Group’s climate targets in accordance with 1.5°C emission scenarios and the Science Based Target initiative’s criteria and recommendations. Already by 2023, the company has achieved positive results towards carbon neutrality.

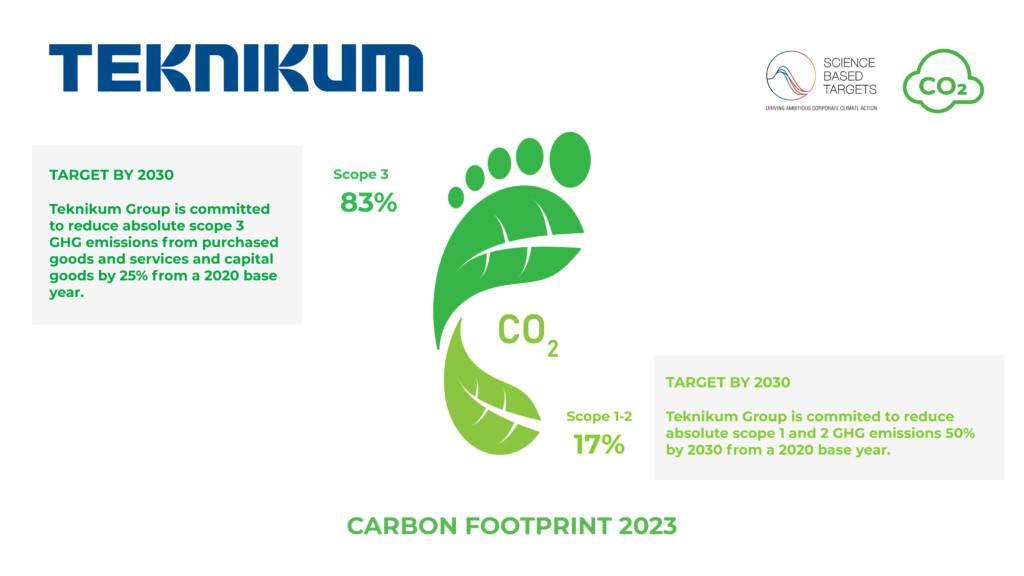

In 2023, Teknikum Group’s carbon footprint consists of 83% of scope 3 GHG emissions and 17% of scope 1-2 GHG emissions.

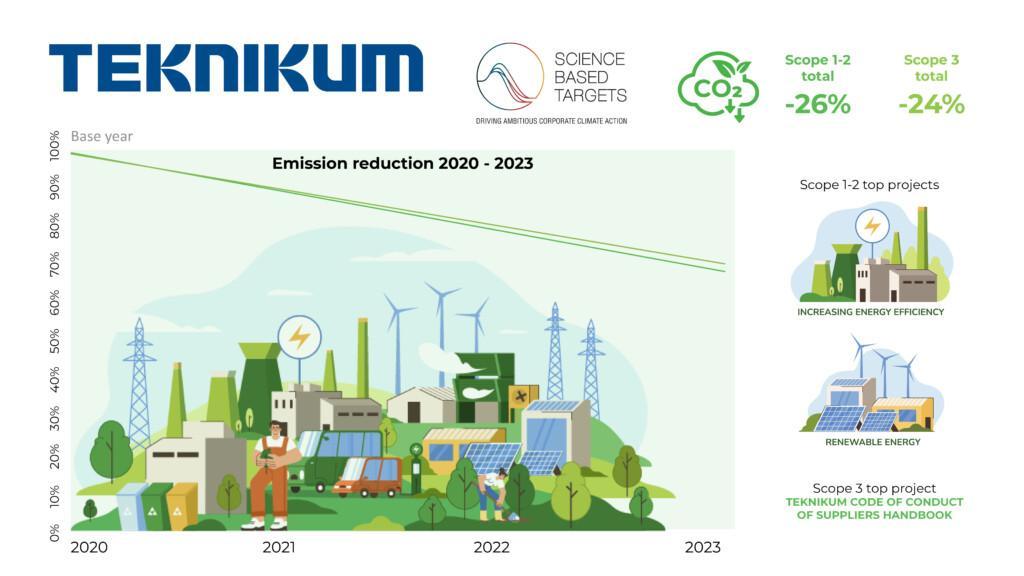

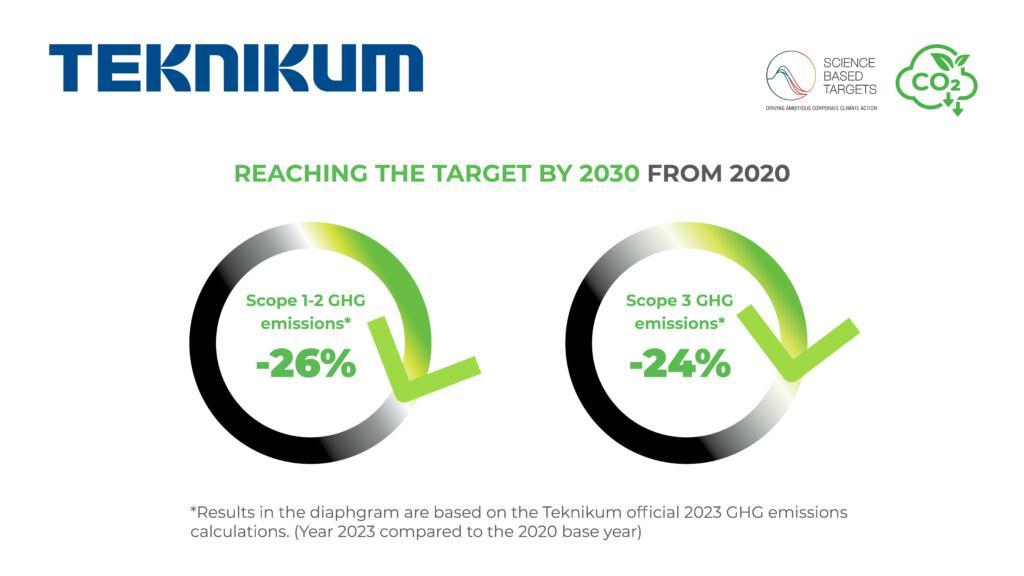

Scope 1 and 2 GHG emissions in 2023: -26% from 2020 base year

Teknikum Group commits to reduce absolute scope 1 and 2 GHG emissions 50% by 2030 from a 2020 base year.

GHG emission categories 1 and 2 include direct and indirect greenhouse gas emissions from the company’s operations. Teknikum Group achieved in reducing its emissions via limiting electricity consumption, purchasing greener energy and reducing the use of self-generated energy.

“Energy-saving measures paid off. We have replaced some equipment and machinery and installed energy-efficient lighting and insulation in factories. We also took steps to transfer to renewable energy in our energy purchasing” explains Mr. Esko Mäntyharju, Director, HSQE of Teknikum Group.

Scope 3 GHG emissions in 2023: -24% from 2020 base year

Teknikum is committed to reduce absolute scope 3 GHG emissions from purchased goods and services and capital goods by 25% by 2030 from a 2020 base year.

Scope 3 emissions are strongly associated with purchased products and services. With its own products, Teknikum is actively looking for suitable recycled and bio-based materials. Products like TEKNICROSS® railway rubber level crossing elements include recycled rubber. Teknikum also introduced industrial hoses made partly from recycled or bio-based rubber materials.

On customer-specific products the environmental impacts are considered via manufacturing process. It’s the whole group’s common goal to reduce scrap materials and recycle. Environmental management is also based on ISO 14001 in all locations.

Teknikum’s principles for good administration have been defined by the board and executive group. The purchase and sustainability policies ensure further development of responsible operations.

In 2023, Teknikum Group published renewed Teknikum Code of Conduct of Suppliers guidelines, which detail the expectations based on ESG standards. The current and future Teknikum suppliers need to confirm that they follow these guidelines in their own operations. Additionally, Teknikum audits its suppliers regularly.

“A cooperation with the suppliers plays an important role in implementing emission reduction measures in the supply chain,” says Mr. Mäntyharju.

Reaching the future 2030 SBTi goals

“In the next coming years, we will focus on continuous development according to our SBTi Roadmap. We have evaluated the possibilities of new energy sources for production needs. Also, in the name of energy efficiency there are plans for increasing heat recovery and reducing electricity & steam consumption”, tells Mr. Mäntyharju.

“The most important way to support our mission in Scope 3 GHG reduction is to enable the availability of new innovative, more sustainable products and solutions to our end-customers”, Mr. Mäntyharju says.

Teknikum Group will report on the progress of its climate work annually on its own communication channels.

Learn more: https://teknikum.com/sustainability/

Teknikum – a pioneer in sustainable polymer technology

Teknikum serves industrial customers in demanding customer-specific rubber, plastic, silicone and foam products. Its high-quality industrial hoses, competitive contract manufacturing services of molded products, and comprehensive rubber and mill lining services ensure efficient processes for customers. Teknikum’s factories and offices are located in Finland, Hungary and Germany. The Group’s operations are guided by three core values: safety, sustainability and sincerity.

www.teknikum.com

Contact

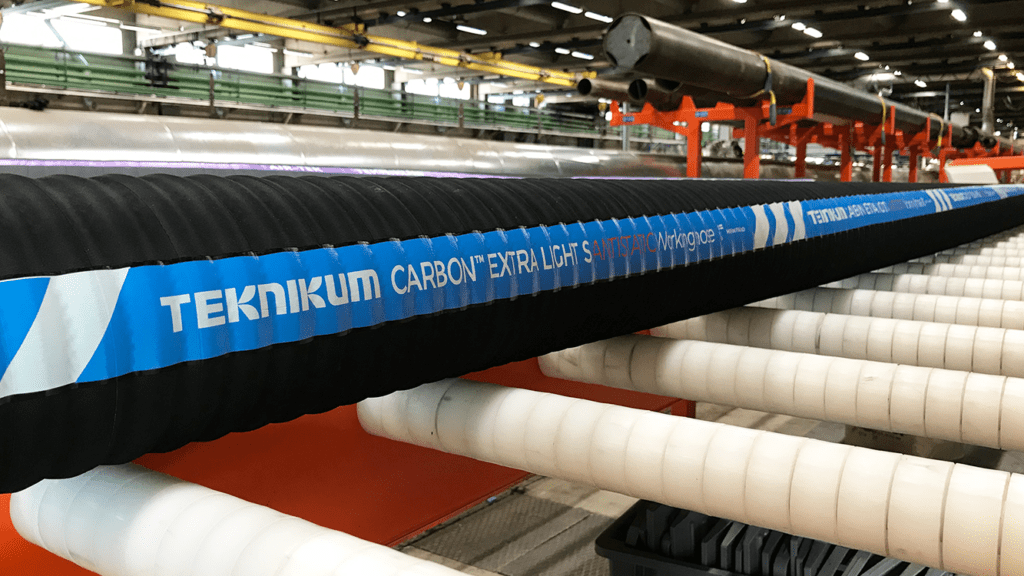

The largest industrial hose factory in the Nordic countries is located in Sastamala, Finland. Teknikum has been manufacturing industrial hoses for over 30 years and specializes in the needs of demanding industry. The development of rubber grades starts at the company’s own laboratory, and high-quality rubber grades are manufactured in Finland at the Kerava factory. For end users, Teknikum promises a very durable, environmentally friendly industrial hose for the transfer of various materials, suitable for either suction or delivery use.

New international growth due to innovations

Timo Kokkonen, Director of Teknikum Group’s Hose Business, looks happily at a new hose reel in the warehouse of the Sastamala hose factory.

“We have launched a new rubber grade for abrasive use. It includes 15% recycled rubber and 60% renewable rubber”, says Kokkonen. “As this new rubber quality is being put into production, we are able to offer a new, environmentally friendly option,” he continues.

Kokkonen knows that the need is real. In the construction and mining industry, customers have received the news of environmentally friendly products with great enthusiasm.

“The overall safety of the product includes the user’s experience and the product’s whole life cycle,” says Kokkonen. “By choosing a hose made in Finland, you can be sure that these aspects of the manufacturing are in order.”

The Teknikum CARBON™ work hose family is suitable for abrasive materials in suction and pressure use. The latest antistatic Teknikum CARBON Extra Light S hose is available with an outer diameter of 89 – 220 mm. The hose can be made to order with spiral-free cuffs to enable easy attachement. The hose is readily available from Teknikum dealers.

An expert in demanding fields

Teknikum specializes in abrasive hoses. The work hose series CARBON contains corrugated, flexible suction delivery hoses and light delivery hoses with a smooth surface. The newest addition to the product family is the antistatic Teknikum CARBON Extra Light S, which is specially designed work hose for vacuum trucks. The hose can be supplied with spriral-free cuffs enabling easy attachement.

Teknikum also serves the chemical and food industries. The versatile MULTI-TEK series is suitable for up to 98% of the most common industrial chemicals. Applications can be found e.g. from the process industry and facilities that require high hygiene. MULTI-TEK series hoses have a very durable EPDM outer surface and an inner surface protected by UPE plastic film. The hoses are suitable e.g. for industrial cleaning in the chemical, pharmaceutical and foodstuff industry.

Available from dealers in Europe

Teknikum hoses are available from experienced industrial retailers in Europe. In customer-specific projects, Teknikum also serves industrial plants and OEM’s directly. As a manufacturer, Teknikum is known from its industry expertise and agility. In addition to hoses, Teknikum offers wide range of hose couplings.

Sales manager Jani Lampinen presents Teknikum GRANIT and TITAN series hose couplings.

Teknikum’s selection includes different and different-sized couplings not only for work hoses, but also for more robust material handling hoses.

Contact

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263Heavy process industry and mining industry

Jani Lampinen

Sales Manager, Industrial hoses BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 411 7810

Timo Kokkonen

Director, Hoses Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 45 7881 3197December 20, 2023 – Sastamala, Finland

Polish publicly traded company Sanok Rubber Company S.A. has signed an agreement on December 19, 2023, to acquire Teknikum Group Ltd. The acquisition includes the entire share capital of Teknikum and is part of Sanok Rubber’s broader strategic expansion.

Mr. Piotr Szamburski, CEO of Sanok Rubber, emphasizes that the acquisition strengthens the Polish company’s position in the market and opens up new business opportunities. “The expertise and strong presence of Teknikum in the industry support Sanok Rubber’s strategic objectives. The collaboration lays the foundation for growth and innovations that will benefit both parties,” comments Szamburski.

Mr. Jani Hämäläinen, CEO of Teknikum Group, sees the acquisition as an excellent opportunity to continue growth and expansion in the Scandinavian and European markets. “This provides Teknikum with an exceptional opportunity to continue its growth and expansion. Collaboration with Sanok Rubber strengthens our position and opens up new possibilities,” summarizes Hämäläinen.

Teknikum is a trusted brand for demanding industrial customers and OEM’s, offering profound expertise with its wear-resistant and environmentally friendly polymer solutions. As part of Sanok Rubber Company S.A., the company will continue providing world-class raw materials, reliable products, and the most efficient manufacturing processes to its customers.

The completion of the acquisition is expected in the coming months, marking a significant milestone for both companies as they aim to strengthen their positions in international markets.

Teknikum – provider of sustainable polymer technology

Teknikum serves industrial customers in need of reliable rubber, plastic, silicone, polyurethane, and foam solutions. Our factories and sales offices are located in Finland, Hungary and Germany. Teknikum’s offering includes pioneering wear-resistant industrial hoses, high-quality technical foam products, and comprehensive contract manufacturing services of the polymer industry. Our values are safety, sustainability, and sincerity. More information: www.teknikum.com

Sanok Rubber Company S.A.

For over 90 years we have provided our clients with the highest-quality products, which comply with all the latest technological standards. We care about the environment and support local communities. We merge tradition with modern thinking every day. Sanok Rubber Company S.A. is the European leader in the field of rubber products, rubber-to-metal articles and combination of rubber with other materials for the automotive, construction, agriculture, pharmacy and household appliances. Sanok Rubber Company S.A. is listed on the Warsaw Stock Exchange and employ more than 3000 people in Europe and North America. More about us: www.sanokrubber.com

September 6, 2023 – Sastamala, Finland

Free for immediate release

Teknikum Group manufactures industrial polymer products in Finland and Hungary. In 2021, the company made a commitment through the Science Based Targets initiative to reduce emissions by implementing measures that science dictates as necessary to avoid the devastating impacts of climate change on society and nature. The SBTi is a collaborative project between the CDP, the UN Global Compact initiative, the World Resources Institute (WRI) and the World Wildlife Fund (WWF). The project aims to involve companies in reducing global emissions to zero by 2050 at the latest and limiting global warming to 1.5°C. In May 2023, the SBTi organization approved Teknikum Group’s climate targets in accordance with 1.5°C emission scenarios and the Science Based Target initiative’s criteria and recommendations.

The green transition at the core of the business strategy

Teknikum Group’s mission is to lead the way in sustainable development in its sector. Its business strategy relies on the green transition and product development investments. Safe solutions in the polymer industry typically stem from materials development, which is one of Teknikum Group’s strengths.

“Teknikum’s Vammala and Kerava plants have developed rubber compounds since the 1950s, when the company was still part of the Nokia Group’s Technical Rubber business. In recent decades, our personnel have further developed materials expertise in several highly demanding application environments that are critical to the functions of society. These include material handling solutions in the rail, process and mining industries, for example. In addition, Teknikum manufactures personal protective equipment for the defense, security and construction sectors,” says Jani Hämäläinen, the CEO of Teknikum Group.

The Science Based Targets initiative proved to be the best tool for promoting product development. Several major industrial corporations in Finland and around the world have found its science-based calculation methods and indicators to be highly effective. Teknikum Group’s choice was also supported by the consistency of the methods and indicators and their comparability with the indicators used by important customer companies.

“The EU requires large companies to report on their emissions, but there is no actual obligation for the green transition. The company’s vision and level of ambition determine whether it beats its competitors in the market with new modern solutions. Teknikum aims to lead the way, so that we can help our European customers ensure safe and environmentally friendly processes in demanding operating environments,” says Hämäläinen.

Ambitious targets for all emission categories

The Greenhouse Gas Protocol (GHGP) is an internationally recognized accounting and reporting standard for determining and managing greenhouse gas emissions. According to the SBTi criteria, companies’ targets must cover GHGP emission categories scope 1 and 2, which include direct and indirect greenhouse gas emissions from their operations. Some companies must also set targets for scope 3 emissions, which result from the company’s operations, but the sources of emissions are not directly owned or controlled by the company.

Teknikum Group Ltd. Commits to reduce absolute scope 1 and 2 GHG emissions 50% by 2030 from a 2020 base year. Teknikum Group Ltd. also commits to reduce absolute scope 3 GHG emissions from purchased goods and services and capital goods by 25% within the same timeframe.

Improvements in energy efficiency, use of renewable energy and cooperation with suppliers

Scope 3 is the largest source of emissions for Teknikum and many other industrial manufacturers. When calculating Teknikum Group’s key indicators, it became clear that most of its emissions were associated with purchased products and services.

“Cooperation with suppliers plays a key role in identifying emissions reduction opportunities and implementing reduction measures in the supply chain,” says Esko Mäntyharju, Director, HSQE, who is in charge of developing emission indicators at Teknikum Group.

“Effective development measures include promoting the procurement of materials with a lower carbon footprint, reducing transport emissions and optimizing packaging.”

In other emission categories, the most effective development measures are related to electricity consumption and the use of self-generated energy in particular.

“We will achieve concrete improvements through energy-saving measures such as the replacement of equipment and machinery, better insulation, and the installation of energy-efficient lighting. We will also need to transfer to renewable energy sources such as solar, wind, biogas or geothermal electricity to the extent that these energy sources are not yet used in our operations,” Mäntyharju explains.

Going forward, Teknikum Group will report on the progress of its climate work annually in its own communication channels and on the SBTi website at https://sciencebasedtargets.org/companies-taking-action#dashboard.

Teknikum Group is Sastamala’s largest employer and one of the region’s largest energy users. Its climate work has a significant impact on the implementation of the green transition in the Tampere Region and in the wider Finnish chemical industry.

Teknikum – a pioneer in sustainable polymer technology

Teknikum serves industrial customers in demanding customer-specific rubber, plastic, silicone and foam products. Its high-quality industrial hoses, competitive contract manufacturing services of molded products, and comprehensive rubber and mill lining services ensure efficient processes for customers. Teknikum’s factories and offices are located in Finland, Hungary and Germany. The Group’s operations are guided by three core values: safety, sustainability and sincerity.

www.teknikum.com

Instagram: @ teknikumgroup

Photo: Maridav – stock.adobe.com

More information

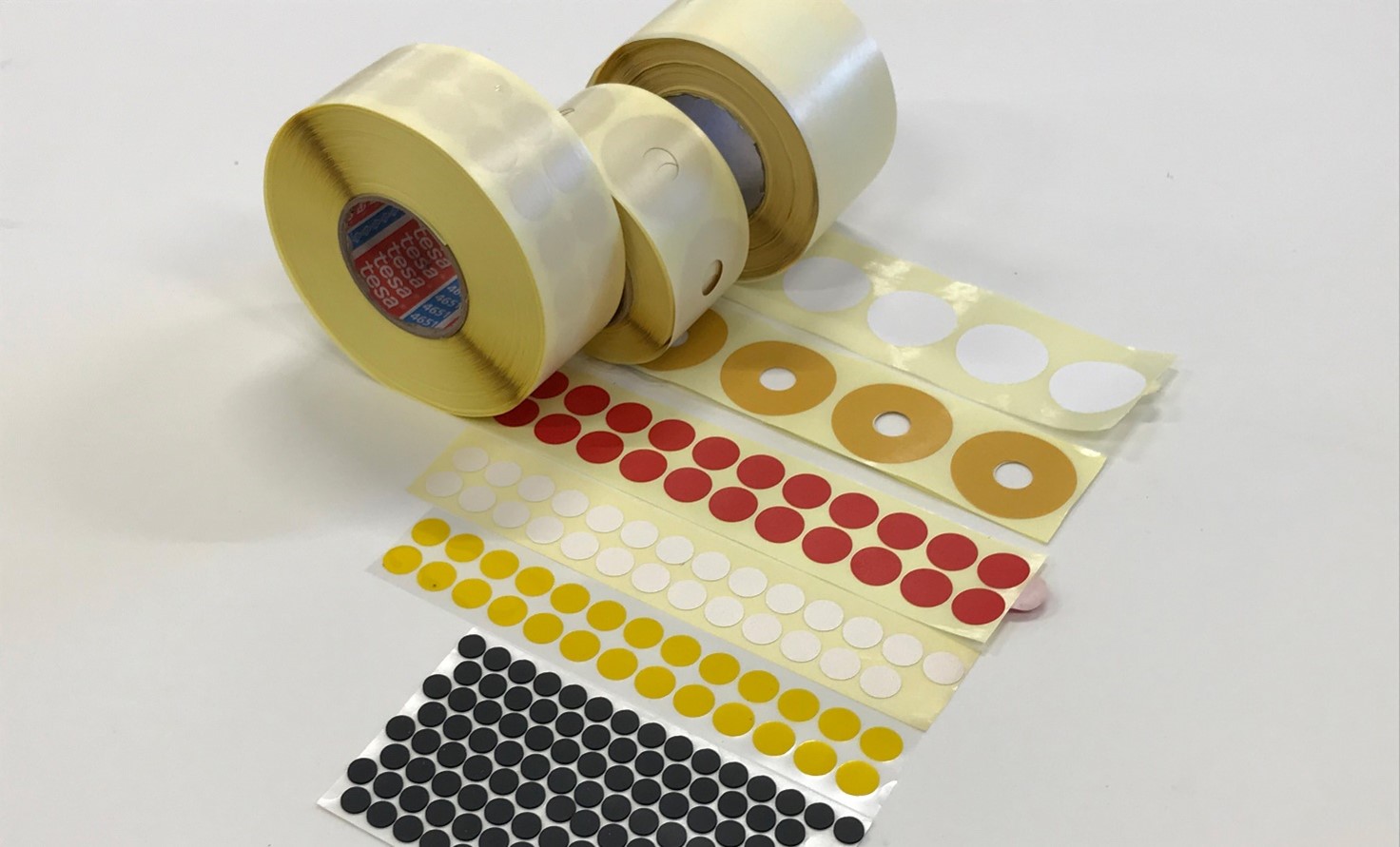

Teknikum combines different polymers, such as foam, plastic and rubber, into one product according to customer’s requirements.

Teknikum is an expert in technical foam converting and plastic parts manufacturing. Teknikum Group has five factories, which are located in Hungary and Finland. The company differentiates from competitors by combining materials to more complex end-products like helmets and half masks. When needed, Teknikum delivers finished assembled products, taking care of the whole manufacturing process. Contract manufacturing projects are done for several international brands operating in personal protective equipment, electronics, machine building, automotive and home appliances industries.

Teknikum Group’s Foam BU Director Mr. Cebastian Doepel is continuously impressed by the efficiency and know-how of his team. The state-of-the-art automated foam and plastic machinery is completed with experienced project team, R&D department and of course the factory workers.

“We have a unique set of skills to serve our customers”, Mr. Doepel says. “From the raw material sourcing to efficient prototype simulation and mass production, Teknikum is one-stop-shop for the customer – whether they are in the product development phase or established in their market”, Mr. Doepel tells.

Typical products for Automotive Industry include different kind of kiss-cut foam and plastic tapes.

Agile partner with know-how

Along with foam converting and moulded product, Teknikum manufactures industrial hoses in Hungary and Finland, has sales office in Germany and wide reseller network in Europe.

The versatile manufacturing experience gives several benefits to demanding customers. The company differentiates from competition by combining plastic parts with foam and rubber and being able to deliver finished assembled products.

“Teknikum’s product development department serves with latest technologies: agile 3D modeling is available with CAD and 3D-printing. Also, both FEM and Moldflow analysis are used for evaluating functionality and durability of the product, ensuring quality finish”, tells Mr. Doepel.

“We have a unique set of skills to serve our customers”, Mr. Doepel says.

“From the raw material sourcing to prototype simulation and mass production, Teknikum is one-stop-shop for the customer – whether they are in the prototype phase or established in their market”.

Simple or complex quality products

Sales Manager Mr. Ádám Boldizsár helps customers with the team to find suitable solution, from early engineering stage to mold deliveries and eventually to a product delivery.

“By using the injection molding, extrusion and 2D/3D cutting techniques, our plastic department manufactures customer-specific special products. Our raw material selection covers all the main grades of thermoplastics, and certain engineering plastics such as POM, PA, and PA-fiberglass compounds. Additionally, our high-tech mold shop manufactures and maintains molds for customer’s projects”, Mr. Boldizsár tells.

Teknikum’s high-tech mold shop manufactures and maintains molds for customer’s projects.

“Some of our products may be very small in size, but here in Jászladány our equipment also enables making very large plastic products with up to 2,000 cubic centimeters in volume with a maximum weight of 4 kg”, Mr. Boldizsár tells.

“With technical foam, we offer wide range of materials, such as light PU, waterproof PE, chemical resistant EPDM, recycled rebound foams and special materials and tapes”, Mr. Boldizsár explains.

Typical volume foam products are done by using kiss-cut or full-cut technologies.

Teknikum Kft. has been operating in Jászladány, Hungary, since 1993. The foam plant offers state-of-the art automated machinery for demanding contract manufacturing.

Sustainability is one of the group’s operational values

Teknikum is committed to Paris agreement via Science Based Target initiative. This ensures that customers can rely on Teknikum’s future-proof sustainable quality, along with ISO and IATF certified production.

“Customers select us, when they are looking for high-quality production with overall cost-efficiency and easy project management”, Mr. Boldizsár says.

“We offer the best of Hungarian manufacturing, combined with Finnish know-how”, Mr. Boldizsár concludes.

Recycled foam allows many benefits when customers can select wanted foam mix features.

Contact us

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263Industrial customers, Moulded products

Satu Hyökki-Siltanen

Sales Manager, Moulded products BU

Teknikum Group Ltd

satu.hyokki-siltanen@teknikum.com

+358 50 468 1181

Ilkka Nieminen

Director, Plastics Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 40 5101 868

Cebastian Doepel

Director, Business Development and Foam & Compounds BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 386 0027For immediate release

Teknikum takes part in the project for development and use of bio-based and antimicrobial materials in protective equipment (BIOPROT) led by LUT University, which received two-year funding from Business Finland in 2021. The purpose of the project is to develop new, sustainable and safe material solutions that can be used, for example, in the fight against infections. The research focuses especially on respirators, surgical mouth and nose protections and reusable protections intended for industrial use. The product development project for the Teknikum respirator, aiming to design and manufacture an ecological industrial solution, has moved into the prototype manufacturing phase.

Teknikum develops a new type of ecological half mask intended for industrial use

Ms. Minna Poikelispää, Chemist at Teknikum and head of the BIOPROT project, says that the work is progressing according to the original plan. The goal is to make the most ecological and compact protector that is comfortable to use. The possibility of adding antiviral properties, i.e. properties that destroy viruses or prevent their reproduction, is also investigated.

During the project, there’s close cooperation with the research organizations involved in BIOPROT, e.g., related to material testing, life cycle analysis and business model. Next, the project progresses to the prototype testing phase, where cooperation is carried out, with e.g., VTT, the Technical Research Centre of Finland.

“Collaboration with research organizations flexibly opens up opportunities for wider testing and analysis than usual. At the same time, Teknikum receives valuable information about the latest developments in the field, which contributes to the growth of the company’s competitiveness on the international market,” says Ms. Poikelispää.

The first preliminary photos published

Teknikum’s product development staff has extensive experience in material development and the production of protective masks. The know-how helps to define the desired properties from the user’s point of view, when a new type of product is under development. The primary requirement, along with the protective power, is comfort of use, which is emphasized with the personal protective equipment required in professional use. In addition to being ecological, high quality requirements have been set for the protector’s structure in terms of skin-friendliness, protection and durability.

On the market in a few years

The goal is to have a new ground-breaking respirator on the market within a couple of years. The final launch schedule depends on the product testing results. However, based on experience and preliminary results, the development team can be confident that the new protector will meet the requirements set for it.

Teknikum is fully responsible for product development, from material development to manufacturing, which enables agile further development. During the product’s life cycle, development needs are assessed based on practical customer feedback, as the goal is to solve customers’ wide-ranging respirator needs in a sustainable way.

The project led by LUT University will continue until the summer of 2024, when the organizations that received funding will submit their final reports on the implementation of the development projects. However, the actual development cooperation will continue based on need until the commercial launch of the product.

Teknikum – a full-service provider of polymer technology

We serve industrial customers in demanding rubber, silicone, plastic and foam solutions. Our factories and sales offices are located in Finland, Hungary and Germany. Our offering includes high-quality technical foam products, reliable premium industrial hoses and contract manufacturing services of the polymer industry. Teknikum Group’s values are safety, sustainability and sincerity. www.teknikum.com

Instagram: @teknikumgroup

More information

Riku Sivula

Director, Moulded products & Linings Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 445 2255Teknikum’s renewed GREEN & SMART abrasive material handling hoses and rubber lined pipes offering is now available in Poland. The products and comprehensive pipeline solution is represented by experienced local sales company Piomet, based in Krakow. Teknikum’s high-quality hoses, bends and pipes are popular solutions due to their long service life and sustainability.

Known for its innovative material development, Teknikum introduced products utilizing renewable and recycled rubber in industrial pipeline components in 2022. The company is a forerunner in wear resistant solutions for highly abrasive environment. Teknikum’s flexible CERAMIC hoses and bends are proven exceptional over a decade in transferring sand and slurry, including coal or iron ore. Completed with expert field-services and engineering know-how, Teknikum has now set foot on Polish market, offering the best possible customer experience for industrial customers.

Teknikum’s customer base represent various demanding industries, Energy and Mining being one of the major ones. Teknikum’s mission is to drive sustainability in the industry.

Piomet’s owner and experienced Business Development Manager Mr. Piotr Świeźawski has already seen good response and interest in the Polish market.

“The power plants and other industrial plants, that handle abrasive materials in their process, are more and more looking into innovative and cost-efficient solutions. The use of recycled materials in a durable and sustainable way gives both cost benefits and environmental safety”, Mr. Świeźawski tells.

Photo: Piomet’s owner Business Development Manager Mr. Piotr Świeźawski.

For over 30 years Teknikum has differentiated from the competition with agile services and offering of the extremely durable CERAMIC smart hoses, wide range of unique lining rubbers, complex rubber lined pipes and customer-specific solutions.

As an example of recent product development, Teknikum brings GREEN & SMART product line to the market. The new hoses include an option of cover rubber compound that includes 60% renewable natural rubber materials of which 15% is recycled. The compound is highly durable and suitable for abrasive materials. It’s designed for Teknikum GRANIT and TITAN Abrasive hoses and CARBON Working hose series. Additionally, Teknikum’s wear and tear resistant inner lining rubber options include up to 80% renewable natural rubber.

The new compounds are developed and tested in Finland in company’s own laboratory in cooperation with technical universities. The testing includes field-testing with selected industrial customers.

GREEN & SMART from the pioneer of CERAMIC hoses

One of the pioneering Teknikum hose products is the flexible but robust CERAMIC hose. The inner lining provides up to 3-10 times the life of a rubber hose or metal tube, depending on the material being transferred. This solution offers sustainable long-life option for transfering granulate substances such as slurry and boiler sand. For example, Finnish power plant Tampereen Sähkölaitos in city of Tampere was able to more than triple the changing period of pipeline. In Poland, similar solutions have been already delivered to various plants dealing with too high maintenance costs.

The sustainable GREEN & SMART hoses are the new innovation from Teknikum, the company focusing on making abrasive material handling easier and maintenance-free.

SMART hoses to level up in process flow management

Teknikum Smart Hose system enables monitoring of wear and tear of inner lining of a hose. The system includes a monitoring device and customer specific Teknikum hose built with monitoring cable. The hose can be selected with rubber or CERAMIC inner lining according to need.

“The system gives a signal when the hose needs to be changed to avoid breakage. Measurement takes place automatically every 60 minutes and a test measurement can be carried out at any time by pressing a button.” Mr. Świeźawski tells about the system.

“Optionally the monitoring is available with single or 1-3 multilayer measurement with several cables built into the hose structure.” Mr. Świeźawski explains. “This system is great for those who want to level up with the planning of maintenance stops and get rid of too frequent ones.”

Safety, innovating and engineering at the core

Teknikum is also known for its innovative Mill Lining products and safe installation services. The company manufactures Steel Top, Rubber and Polyurethane Mill Liners for mills that need grinding result optimizing. The constant problem solving is a core of competence along with wear resistant rubber compounds development and project management.

“In addition to hoses and lining, Teknikum’s services include manufacturing mill lining components with different reinforcements and latest fixing methods. The safe mill lining installation services include supervision, high-quality measurement, and lifetime estimation technologies”, Mr. Świeźawski tells.

“It’s our target to understand each customer’s process needs and deliver fitting solutions.”

Contact PIOMET: sales@piomet-cnc.pl

Banner photo © [netsay] /Adobe Stock

More information

Martti Jokela

Director, New Business Development

Teknikum Group Ltd, Central Europe

firstname.lastname@teknikum.com

+358 50 306 2172Teknikum Kft. has been awarded a grant of 2.041.105,- HUF, 50 % intensity, under the labour market program GINOP Plus-3.2.1-21 ‘Improving the adaptability and productivity of workers and enterprises through labour force development’.

The company’s employees will participate in two training programs. With the competences to be acquired in the training programs won during the project, Teknikum employees in Hungary will be able to perform their tasks to the highest standards – in accordance with the expectations of the customers, providing excellent quality services.

The aim of participating in the training programs is to improve communication efficiency, speed up task management and improve process management, which will help to strengthen the company’s market position, retain jobs and strengthen the local economy.

ABOUT THE PROJECT

- Name of beneficiary: TEKNIKUM Kft.

- Project name: GINOP Plus-3.2.1-21 ‘Improving adaptability and productivity of workers and enterprises through workforce development’

- Contracted amount of aid: 2.041.105,- HUF

- Rate of aid: 50 %.

- Expected date of completion of the project: 30.04.2023.

- Contract No: JNM/01/009790-5/2022

- Place of implementation of the project: 5055 Jászladány, Tisza utca 4.

Contact for more information

Attila Kerekes

General Manager, Hungary

Teknikum Kft

firstname.lastname@teknikum.com

+36 30 458 4645There are many talented people working Teknikum, sometimes settling for less than they are capable of, in a modest Finnish way. And while there is nothing wrong with staying in your comfort zone in a pleasant working environment, there is true value in pursuing for more while testing your limits. When interviewing Lauri Peurala, who has taken the opportunity to educate himself further, one can sense Teknikum has given him just the right kind of push.

Values to root for

Molded products business unit project worker Lauri Peurala has been working for Teknikum for ten years now, in a variety of jobs. A workplace, which invests in safety and well-being of their employees, is a place Peurala has no desire to leave from. Sustainability is also a value Peurala gladly shares with Teknikum, and one can hear pride in his voice, when he talks about Teknikum’s innovations for a greener planet.

And when it comes to employee benefits, Peurala says they are better at Teknikum than many other companies: “When I’ve talked to my friends about this, I’ve come to realize that what Teknikum offers, is special.”

In addition to good benefits like E-passi, bicycle benefit and extensive occupational health care, Peurala mentions Teknikum staff has the possibility to be part of employee sickness fund which offers subsidies for its employees’ expensive laser eye surgeries in Finland.

“That is definitely something you don’t see every day, “ Peurala sums up.

Long-awaited return to school bench

Peurala has applied for different schools for some time now – and in most cases would have gotten in. But a shift from steady work to studying felt too much of a sacrifice, and so Peurala has let many opportunities pass. This is exactly the kind of dilemma Teknikum aims to solve, by offering its workers a chance to study – while getting paid at the same time.

In January 2022 Peurala finally started school, aiming to graduate as a Bachelor of Engineering. Studies are arranged through a combined teaching program, which is a mixture of working days, school days and remote learning. Teachers come from Tampere University of Applied Sciences (TAMK), but contact learning is arranged in many nearby municipalities.

Peurala works at the same, and he has already been given a job with much more responsibility than before. The combination is not easy, but Peurala welcomes the challenge.

“It truly feels I have given my all after a long day at school or work – or both. Hitting the gym after using your brain to their limit, gives an amazing sense of relief and accomplishment.”

More opportunities for young people

When talking about the gym, Peurala mentions his background in sports institute graduated sports advisor, and adds that he is still an avid floorball and ice hockey player in his spare time. It feels natural to then ask him about Teknikum All Stars scholarship program that has been running for a few years now. The program is part of Teknikum corporate responsibility and communications strategy. Its main goal has been to support the goal-oriented pursuits of local children and young people.

Peurala holds these ambitions in high regard, and he says with great experience: “You can never put too many resources into, for example, youth sports. I was lucky I got to strive in any sport I ever wanted as a child, and I wish the same opportunity for every young people. I’m proud of my employee’s contribution in this matter.”

Peurala seems to be in a good place now, and grateful for the opportunities he has been given throughout his life. There is plenty of work ahead for him. Still, Peurala remains curious and optimistic about the future – and eager to prove himself.

Read more

Learn more

Arja Sarkanen

Director, Human Resources

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 40 715 8355