Teknikum’s ceramic hose enables maintenance-free process in the power plant’s boiler sand transfer

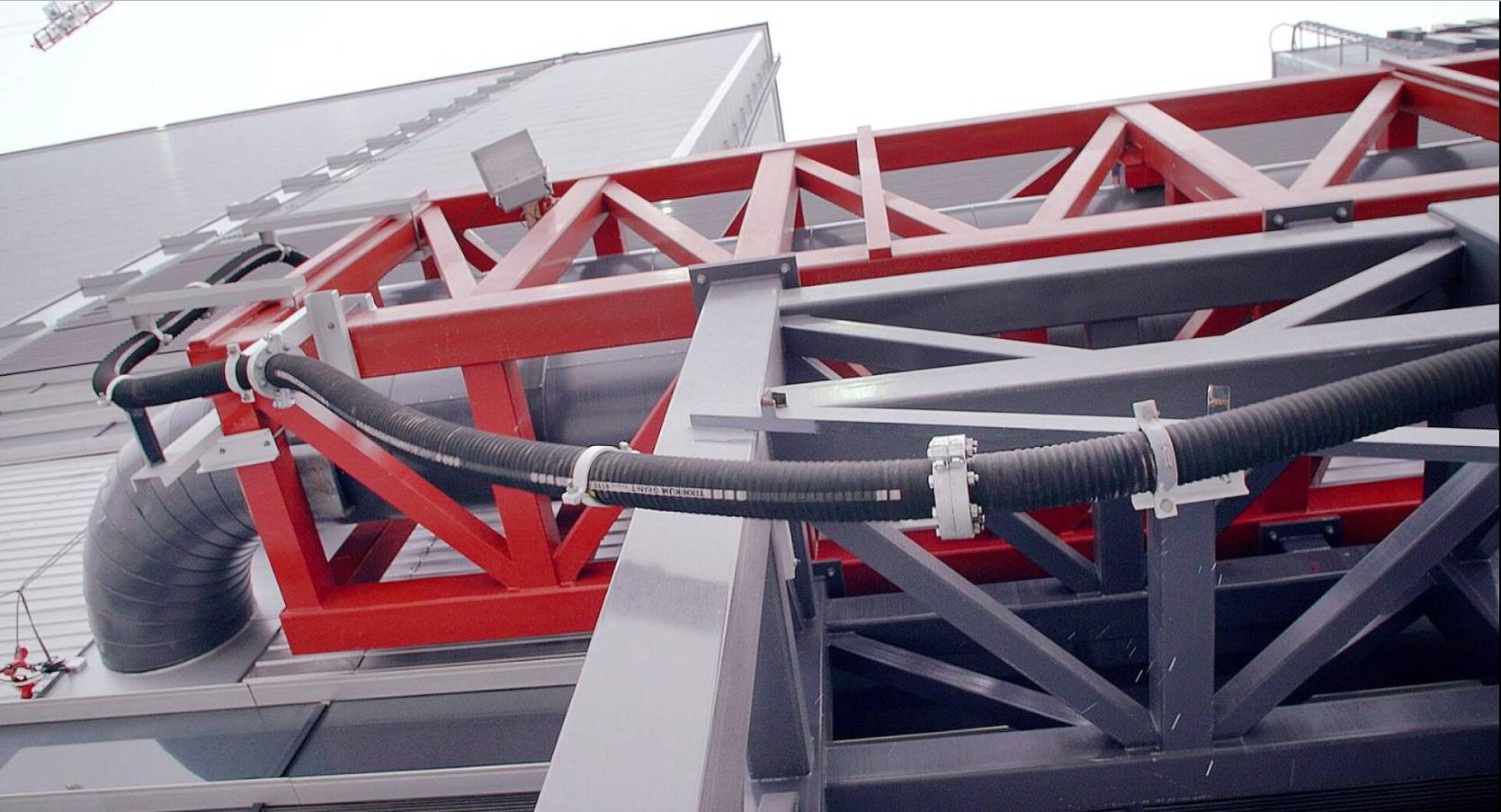

Heat production at Tampere’s Naistenlahti power plant is intensified by boiler sand, which is consumed in boilers by tons every week. The sand is transferred to the power plant’s silo with the help of Teknikum’s hose innovation, along a ceramic material transfer hose developed and manufactured in Sastamala Finland.

A tank truck reverses at the power plant’s yard and the driver attaches a hose that transfers huge masses of sand to the power plant’s silo via a connector. Soon 16 tons of boiler sand erupt from the tank truck as strong impulses to the power plant’s furnace. The rubber hose must withstand relentless wear as the sand shakes with force in the bends of the hose. The transfer of boiler sand is made possible by the result of hundreds of hours and several years of product development: a rubber hose with a ceramic-coated inner surface.

Mr. Jari Perälä, a maintenance engineer of Tampereen Energia’s Naistenlahti power plant, follows the transfer of sand from the tank truck with confidence.

– This ceramic hose has significantly reduced maintenance needs, Mr. Perälä sums up the biggest advantage of Teknikum’s hose product for the power plant.

The ceramic inner lining lasts up to years where the previous metal pipe was worn out in a few months.

– – –

The puncture-proof rubber-ceramic hose increases occupational safety, protects the environment and reduces the risk of production delays. We manufacture industrial hoses in all size classes, for demanding applications from the transfer of soil materials to acids and oils.– Markku Haaranen, Teknikum

Nordic top product also for export

Teknikum’s Product Manager Mr. Jarkko Kalliomäki is pleased that long-term development work has opened up new business opportunities and strengthened Teknikum’s future.

– We have supplied hoses to the energy industry, the forest and paper industry and especially to the mining industry, but also to the steel industry. The latest customer segment is waste treatment and recycling plants, Kalliomäki describes the expanded customer base.

Teknikum has been manufacturing material transfer hoses for the demanding industries for decades and has customers in the Nordics and around Europe.

– The ceramic hose combines the great features of a rubber hose, such as easy installation, flexibility, easy adaptability of transmission lines and damping properties, Mr. Kalliomäki multiplies the great features of the product.

– We are able to manufacture almost all of our hose products with a ceramic inner surface. From small material transfer hoses to large heavy hoses up to a meter in diameter.

The hose is suitable for the transfer of highly abrasive materials, such as mining slurry, lime powder, coal, quartz sand and granules, in areas where it is desired to reduce and avoid continuous service interruptions caused by hose replacement. The market is global.

Teknikum also offers couplings and special hose solutions with fast delivery from factory stock.

Sustainable development and continuous improvement

Teknikum’s sales manager Mr. Markku Haaranen remembers well how the cooperation with the Naistenlahti power plant, owned by Tampereen Energia, started few years ago.

– Our local dealer was able to advise the power plant’s maintenance manager to contact us with the need for a customer-specific solution. Together with the dealer and customer, we got to the site and learned the challenges of the plant’s material transfer. When the original metal pipe was upgraded to a extremely durable Teknikum GRANIT Ceramic hose, the reliability and efficiency of the customer’s production process improved significantly. The ceramic inner lining lasts for years where the previous metal was worn out in a few months, Haaranen recalls.

Haaranen is rightly satisfied with the solution.

– Many have tried to copy the structure of our innovative hose, but so far only Teknikum knows how to produce a high-quality ceramic lining on a curved surface. As a Nordic manufacturer, we want to spread the useful good news of our solution to European industry.

The puncture-proof rubber-ceramic hose increases occupational safety, protects the environment and reduces the risk of production delays. We manufacture industrial hoses in all size classes, for demanding applications from the transfer of soil materials to acids and oils.

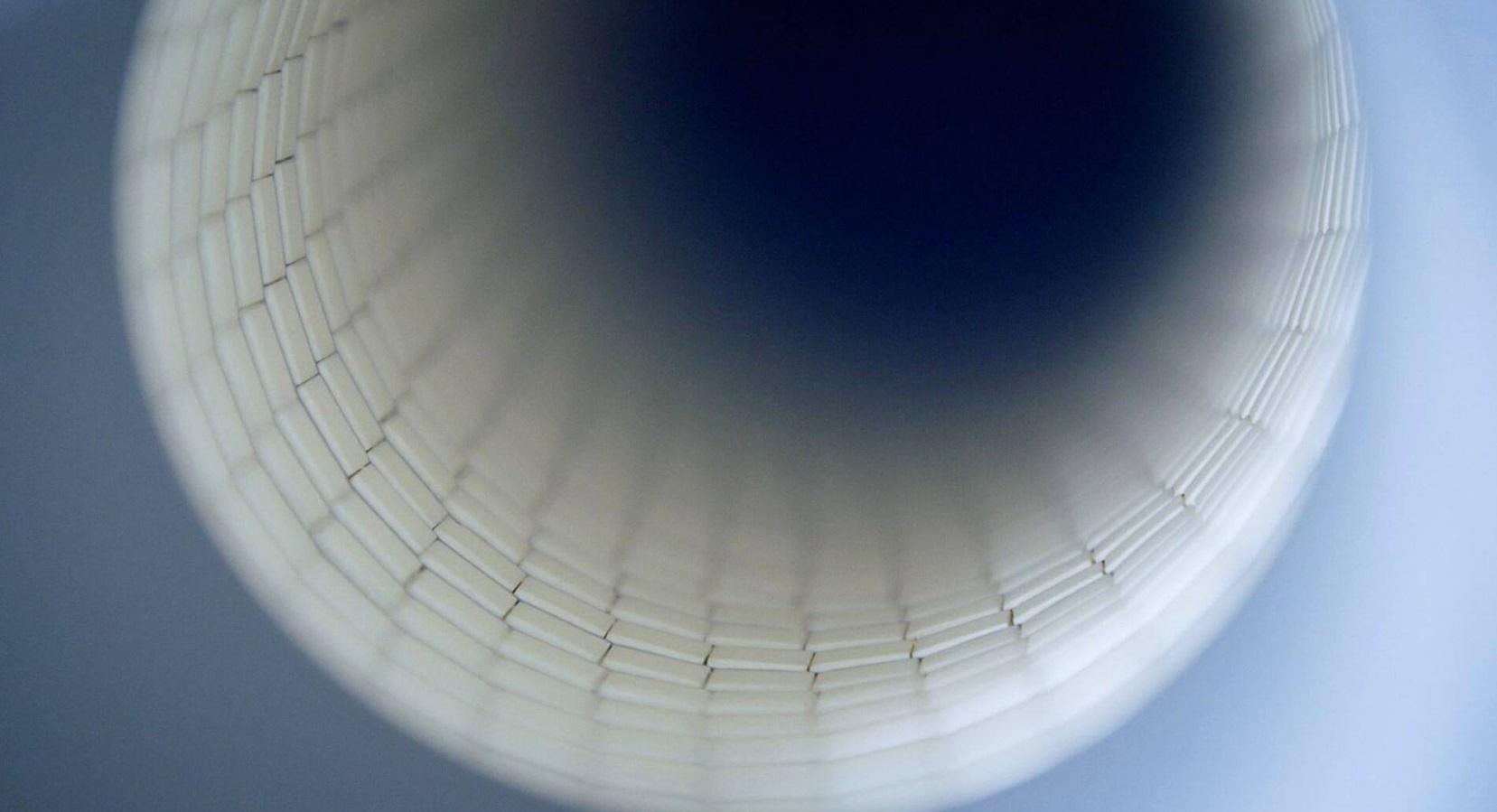

The ceramic lining on the inner surface of the rubber hose withstands the transfer of abrasive materials such as sand and sharp stones while remaining flexible and easy-to-use.

++ Ceramic hose is original Teknikum innovation, providing 3-10 times longer life than rubber hose

++ Only Teknikum knows how to produce a high-quality ceramic lining on a curved surface

++ Ceramic hose line maintains its flexibility due to the innovative structure

++ Teknikum Ceramic hoses are available as stock products with corrugated cover (Teknikum GRANIT Ceramic) or smooth surface (Teknikum TITAN Ceramic)

++ Also custom hoses, bends and connection hoses are available with fast shipping directly from factory

++ Hose couplings and flange solutions are part of Teknikum’s offering

Applications

Teknikum GRANIT® CERAMIC ANTISTATIC is an extremely wear resistant and long-life version of Teknikum GRANIT® hose. The inner lining of the hose is made of ceramic.

The hose is well suitable for transportation of very abrasive materials, e.g. sludge, powdered lime, carbon, quartz sand and granulates in applications where frequent maintenance breaks and hose replacements are not desirable.

The hoses special manufacturing and vulcanization process provides excellent adhesion durability between rubber and ceramics.

Advantages

- Safe and durable hose

- Extremely high wear-resistance

- Ceramic lining provides longer life cycle in comparison to rubber hoses

- Very flexible and low bending radius due to corrugated cover and ceramic-rubber lining structure

- High burst pressure ≥ 32 bar

- Eliminates vibrations and noise

- Excellent weather-resistance

- Quick and easy installation

Contact us to learn more

Martti Jokela

Director, New Business Development

Teknikum Group Ltd, Central Europe

firstname.lastname@teknikum.com

+358 50 306 2172