Swedish ore mining companies trust Teknikum’s high-performing GRANIT CERAMIC hoses

Solving the challenge of handling iron ore, one of the most aggressive minerals in terms of wear rate

Teknikum’s partner in Sweden, GMKAB, has since 1994 performed maintenance work for Swedish mining companies. They have extensive experience with slurry hoses, such as Teknikum GRANIT and Teknikum GRANIT CERAMIC, and rubber lining services for over twenty years. GMKAB’s team also performs service, maintenance, and installations in the field and offer turnkey solutions for the local mining industry.

Sweden is the largest sources of iron ore in Europe – covering about 90% of Europe’s reserves. Although many things built up the effect of abrasion in a pipeline, including slurry density, particle size, flow rate, bends and installation angle, material shape and temperature, it is one of the most abrasive materials to handle. Thus, finding the right slurry hose solution is the key for efficient pipeline management.

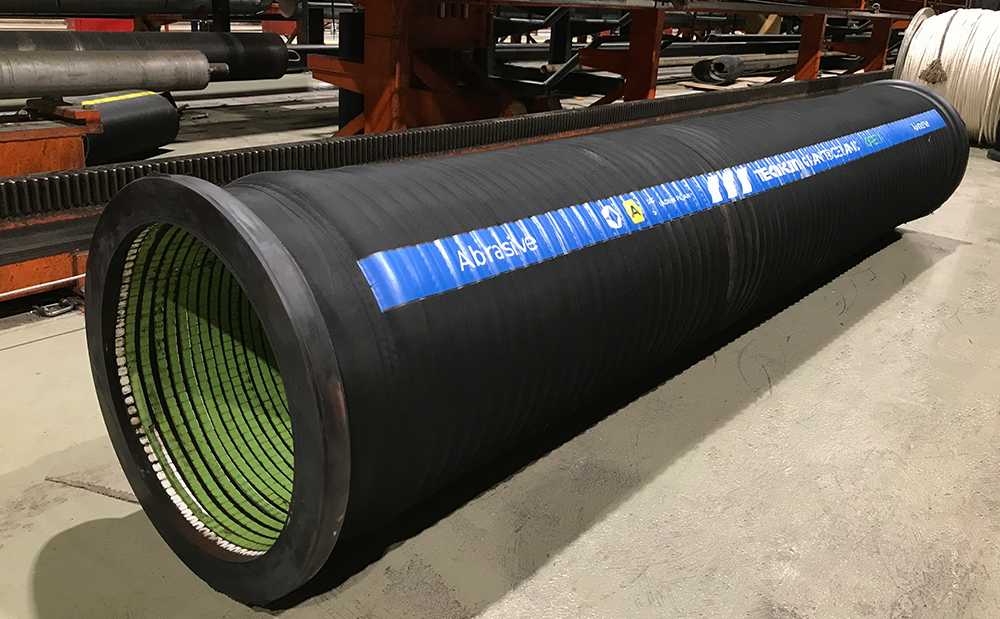

The optimal choice for e.g. concentrator plants proved to be sustainable longlife Teknikum GRANIT CERAMIC abrasive material handling hose.

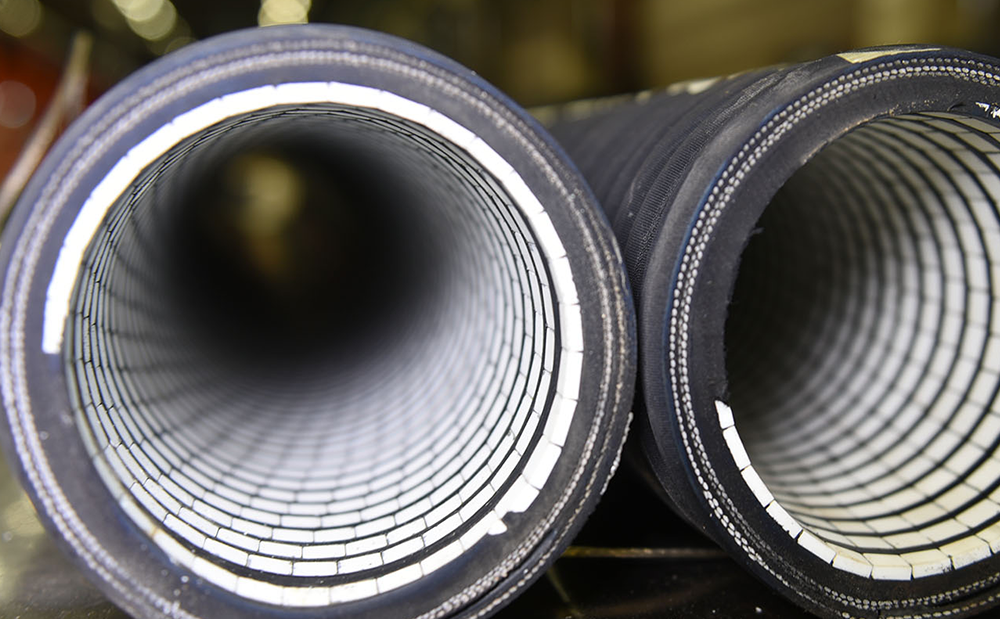

Teknikum’s pioneering CERAMIC lining has proven optimal for GMKAB’s customer’s material handling requirements. It provides 3-10 times longer life compared to rubber hoses or steel pipes, depending on transferred material.

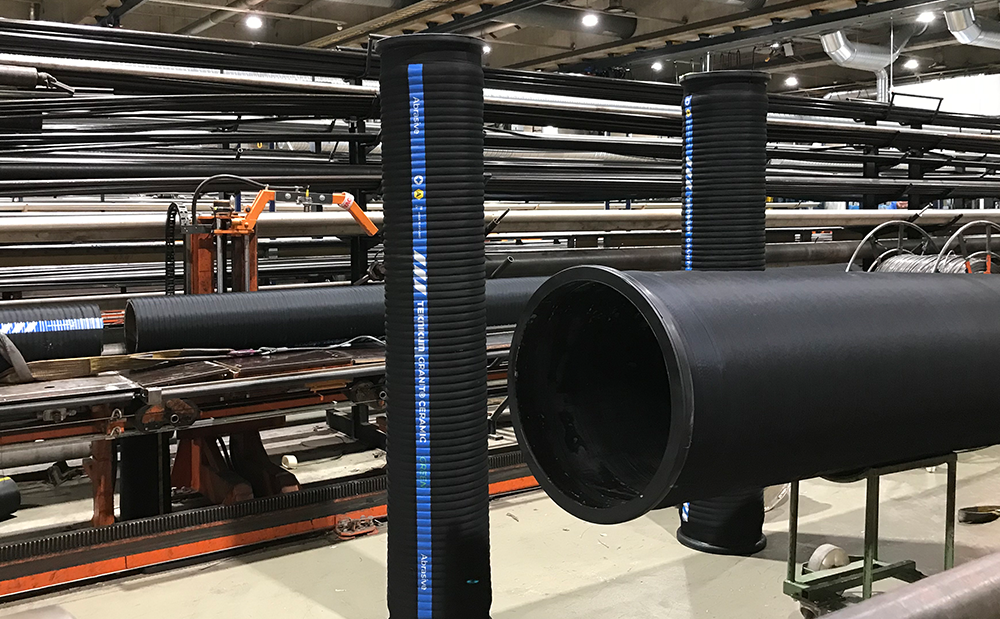

Made in and for the Nordics

As the only Nordic abrasive hose manufacturer, Teknikum enables fast stocking and deliveries for the local the mining partners and customers in Europe.

GMKAB works in a close coopeartion with its customer’s maintenance departments. The customers appreceate their comprehensive services and selection of high-quality products.

In most projects, the end-customers can benefit from the low delivery costs and fast service, when the manufacturer and service partner are situated close by in the Nordics region. In case an agile development project or a customized hoseline is needed, that can be done easily as well. Teknikum’s product development team works in close cooperation with hose operators.

We have received very positive feedback about Teknikum’s abrasive GRANIT CERAMIC hoses from our demanding mining customers.

– Mattias Videhall, Site Manager, GMKAB

Teknikum GRANIT CERAMIC hose manufactured with PLUS Flange is the chosen solution by many of the Mining customers. The long-lasting lining and reliable connection with rubber bead and a flange tightened behind the bead, enables high wear and pressure resistance.

In addition to GRANIT abrasive material handling hoses, Teknikum abrasive material handling solutions include PLUS Flange hoses, enabling free, undisturbed central flow in the connection point. For sections where’s need of inflexibility and permanent load bearing capacity, Teknikum manufactures rubber lined steel pipes and rubber compounds.

Superior wear-resistant with Teknikum’s rubber compounds

Teknikum’s rubber compounds, such as WEAR SAFE 40 and WEAR SAFE 60 are typically used by GMKAB for local rubber lining projects. The special composition and hardness of the rubber compounds have been developed to meet the properties desired in the mining application, such as wear and chemical resistance. As a company driving sustainability in polymer technology, Teknikum is the forerunner in developing compounds according to continuously evolving REACH regulations and high customer requirements.

Top photo: © Adobe Stock/ Charlotte

Contact us to learn more

Mill Lining Services

Samu Grönroos

Sales Manager, Linings BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 337 5843Heavy process industry and mining industry

Jani Lampinen

Sales Manager, Industrial hoses BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 411 7810