Teknikum® Steel Top Lifters

Applications

Teknikum® Steel Top Lifters give longer lifetime for mill linings in specific conditions: wear resistant steel top and elastic rubber body creates the combination, which is especially good in circumstances where lifter bars must take sharp hits of grinded mineral and media. In places where steel is too hard and brittle, and rubber is too soft, the steel coated rubber lifter bars is the solution. Steel on the top protects the rubber body, but the rubber body maintains the elasticity of lifter bar which protects the steel.

The quality of steel and model will be chosen for every purpose differently. Hardness and type of the steel must be chosen according to grinding and process parameters. In some applications lifters are accompanied with steel coated shell or head plates. These are available on request.

Steel Top lifters are part of Teknikum Steel Top Mill Lining Solution.

All lifter bars are moulded and tailor made for the customer mills and processes.

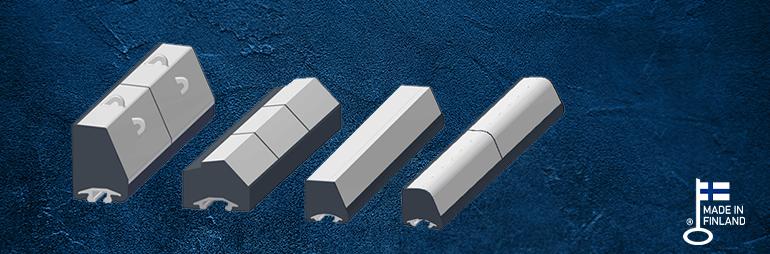

Versions

- WS – Wear Resistant Steel Top lifters are for heavy / medium grinding processes. With wear resistant Steel Top. The thickness and hardness can be selected for every purpose process separately. Thickness of steel can vary 10 – 80mm.

- CSL – Cast Steel Light lifters are for medium grinding processes. The cast steel top is lighter than in our other cast iron top lifters, which makes the installation and handling easier.

- CSH – Cast Steel Heavy lifters for heavy / medium grinding processes. The cast steel top is thick and it can take heavy hits for example in a ball mill.

- CSHD – Cast Steel Heavy Duty lifter for heavy grinding processes on primary mills. For the applications, where high cast Steel Top lifter bar is needed. The cast is thick and can take heavy hits.

Advantages

- Longer lifetime for mill linings

- Excellent wear resistance

- Easy installation