Proactive preparation ensures compliance and full traceability for our customers

Teknikum Group has completed its preparations for the upcoming EU Deforestation Regulation (EUDR) to help customers ensure compliance with the regulation well ahead of the official enforcement date of December 30, 2025 for medium and large companies. The EUDR aims to prevent products linked to deforestation from entering the EU market. Teknikum is committed to supporting our customers in navigating this change by offering fully EUDR-compliant products, systems for supply chain transparency, and clear documentation for each delivery.

What our customers can expect

- EUDR-compliant products with traceable raw material sourcing

- TRACES reference numbers provided per item/order line as soon as the EU system is live

- Clear labeling of exempt products manufactured with materials sourced before December 31, 2025

Our goal is to make your compliance process seamless. Teknikum will include all required documentation to support your internal due diligence and reporting needs.

How EUDR affects our Customers

- Customers will receive documentation confirming Teknikum’s EUDR compliance

- Documentation will include TRACES reference numbers for full transparency

- No action is required from customers for exempt products (with raw materials sourced before the cut-off date)

- Teknikum’s internal systems are designed to align with and support your organization’s own EUDR compliance process

Sustainability is in our core values

At Teknikum, we are guided by our values: Safety, Sustainability, and Sincerity. These principles are reflected in every part of our operations, from raw material sourcing and product development to customer communication and compliance. We see EUDR not only as a regulation but as an opportunity to reinforce our commitment to responsible sourcing and environmental accountability.

If you have questions about Teknikum’s EUDR-compliant products or need support with documentation, please don’t hesitate to get in touch with our team.

Related topics: Sustainability at Teknikum material sourcing and compliance

Contact us

Teknikum Group is proud to continue its partnership with the Finnish Gymnastics Federation by supporting the Men’s Artistic Gymnastics National Team also in 2025. This cooperation reflects Teknikum’s commitment to responsible business practices and to promoting Finnish performance – in both sports and industry.

Originally a two-year sponsorship agreement, the partnership has now evolved into a long-term collaboration based on shared values and real, measurable impact.

Teknikum’s support has been invaluable

– We are extremely grateful for Teknikum’s support and happy that this important collaboration continues, says Oskar Kirmes, National Team Coordinator and Captain.

– With Teknikum’s help, we’ve been able to advance our national program both in training and competition. The support has enabled athletes of different ages to pursue their goals – and the results speak for themselves.

Concrete results on the international stage

The partnership has contributed to impressive international success:

- Emil Soravuo’s World Championship bronze on floor (2021)

- Joona Reiman’s European Youth and EYOF gold on vault (2022)

- Finland’s best team result ever – 10th place at the 2024 European Championships

Supporting the entire gymnastics ecosystem

The national team currently includes 57 athletes across three levels:

- Senior National Team: 12 gymnasts

- Junior National Team: 21 gymnasts

- Youth Development Group: 24 gymnasts

Teknikum’s support helps strengthen the entire system – not just the elite level. This mirrors Teknikum’s approach to product development: long-term investment in talent, structure and performance at every stage.

Shared values drive the partnership

The collaboration is built on mutual values: safety, quality, ambition, and responsibility. These principles are central to both artistic gymnastics and Teknikum’s industrial operations.

In gymnastics, responsibility means providing a safe, supportive, and motivating environment for athletes. At Teknikum, it means offering durable, safe, and customer-focused solutions – designed with the same care and precision.

As an expert in polymer products, Teknikum sees a clear parallel between the qualities required in sport and those expected of technical materials: flexibility, resilience, and strength. Whether in the gym or on the factory floor, these values unite our efforts.

Learn more about Teknikum’s commitment to sustainability and social responsibility:

Teknikum Group has officially joined Mining Finland, a national business ecosystem that promotes sustainable and high-tech Finnish mining solutions globally. By joining the network, Teknikum strengthens its position as a trusted partner in the mining industry and opens new paths to bring our expertise to international markets.

Proven Expertise and Local Manufacturing for Demanding Mining Environments

Teknikum has decades of experience in designing wear-resistant, antistatic rubber and polymer products for mining applications. Our offering includes:

-

Durable industrial hoses for demanding material transfer

-

Rubber linings and protective coatings for silos and equipment

-

Customized polymer solutions tailored for harsh conditions

With in-house R&D and domestic manufacturing in Finland, we ensure high-quality service close to the customer.

Collaboration for Sustainable Growth

Mining Finland connects leading technology providers, service companies and research organizations in the Finnish mining sector. Teknikum brings to the network our deep knowledge of polymer engineering, wear resistance and customized solutions for heavy industries.

Through this collaboration, we aim to contribute to the development of more responsible and efficient mining operations — reducing environmental impacts while increasing operational safety and reliability. As part of the network, Teknikum will also take part in international events and delegations, helping to showcase Finnish mining expertise to the world.

Together with the other members of Mining Finland, we look forward to creating smart, sustainable mining solutions for the future.

We are looking for a passionate and technically skilled Product Manager to lead the development and lifecycle management of polymer products for filter presses—critical components in solid-liquid separation across industries including mining, wastewater treatment, chemicals, and food & beverage. In this newly established role, you will be responsible for driving the creation and launch of an entirely new product portfolio. You will play a pivotal role in shaping the growth and strategy of this business area, focusing on innovation and expanding its presence in critical industrial applications.

Key Responsibilities:

· Lead product strategy, development, and continuous improvement of polymer components for filter presses, ensuring durability, and performance in demanding filtration environments.

· Collaborate closely with R&D, engineering, and manufacturing teams to design, test, and launch innovative polymer solutions tailored for pressure filtration.

· Conduct market research to identify customer needs, industry trends, and competitive benchmarks, translating insights into actionable product roadmaps.

· Engage with customers and sales teams to provide technical support, gather feedback, and ensure products meet application-specific requirements.

· Support marketing and sales activities with technical expertise and product training.

What We Expect from You?

We value your proactive and hands-on approach to product management, combined with strong technical expertise and a commercial mindset. At Teknikum, we appreciate individuals who are self-driven, curious, and committed to continuous learning and improvement. A structured and persistent working style is key to succeeding in this role, as product development projects often span over several years and require careful follow-up. You will thrive in our team if you are motivated by collaboration, eager to work closely with both customers and internal stakeholders, and ready to take ownership of driving product development initiatives forward.

Qualifications

· Bachelor’s degree in Mechanical Engineering, Mining Engineering, Chemical Engineering, or a related field; advanced degree or MBA is a plus.

· Minimum 5 years’ experience in engineering, product management, or technical sales within the mining or process equipment industries.

· Deep understanding of industrial filtration and dewatering technologies. Strong technical-commercial mindset, with the ability to identify market needs and drive product development accordingly.

· Proven track record of cross-functional leadership and project management.

· Strong analytical, communication, and problem-solving skills.

· Fluent English language skills are required. Finnish language proficiency is considered an advantage.

Your location can be anywhere in Finland. However, during the initial period, regular presence at our headquarters in Sastamala is required. The position also requires willingness and ability to travel globally on a regular basis.

What We Offer You:

We offer you an exciting and challenging opportunity to shape and develop a brand-new product portfolio and business area within an innovative polymer company. You will play a pivotal role in creating and driving the growth of this new area, working alongside a motivated and professional team. Although this product portfolio is new, you’ll leverage our established presence and strong customer relationships in the mining industry.

We offer our employees a range of benefits including epassi, sports activities, massages, bicycle benefits, and various other services.

Application Process:

Please submit your application, CV, and salary requirements via our recruitment partner Compass HR Group at https://urly.fi/3Pw8 by May 18, 2025. Interviews will begin during the application period, so we encourage you to apply promptly.

For more information about the position, contact Heikki Valtonen Compass HR Group, tel. 0400 708 162 or heikki.valtonen@compasshrg.fi.

Teknikum – A pioneer in sustainable polymer technology

Teknikum serves demanding industrial sectors with customized rubber, plastic, silicone, and foam product solutions. Our high-quality and reliable industrial hoses with the Finnish Key Flag Symbol, competitive contract manufacturing services for molded products, and comprehensive rubber lining and mill lining services ensure the efficiency and competitiveness of our customers’ processes.

Teknikum’s factories and offices are located in Finland and Hungary. The operations of the group are guided by our core values: safety, environmental responsibility, and sincerity. www.teknikum.com

Teknikum’s Sastamala plant hosted a hands-on Personal Protective Equipment (PPE) demonstration, aiming to make workplace safety even more visible and practical in our daily operations. The event was part of our continuous effort to improve occupational safety and support employee well-being.

During the day, employees had the opportunity to explore a variety of protective solutions, test different equipment, and consult directly with experts. Several PPE suppliers were present to introduce the latest innovations and demonstrate how their products can support safety across different working environments.

The demonstration included:

-

Cut-resistant gloves and arm guards for handling sharp materials safely

-

Chemical-resistant gloves, suitable for production environments and laboratory use

-

Hearing protection, designed for different noise levels with user-friendly features

-

Respiratory protection against dust, chemicals, and other airborne hazards

-

Safety knives, showcased as an option to reduce hand injuries during cutting tasks

Safety and well-being go hand in hand

The atmosphere of the event was positive and engaging. Coffee and light refreshments created a relaxed setting that encouraged open conversation and experience sharing. Employees were able to ask specific questions related to their roles and receive personalized recommendations for suitable protective gear.

Occupational safety is a core value at Teknikum. Our goal is to ensure that every employee has access to safe tools and up-to-date information on protective practices. Events like this PPE demonstration are a great example of how safety can be developed in an inclusive, everyday way.

“Even small improvements in protective gear can have a big impact on safety and comfort at work. It’s great that our people can try things themselves and choose what works best,” said Tero Suominen, Teknikum’s Safety Manager, during the event.

On April 3rd, 2025, Teknikum had the pleasure of hosting members of the Nolla Tapaturmaa (Zero Accidents) Forum as part of the network’s company visit initiative. The purpose of the visit was to explore Teknikum’s occupational safety practices and gain insight into how a strong safety culture is embedded in daily operations.

Openness and experience sharing

The visit began with a relaxed coffee session in the canteen, where participants introduced themselves and shared their experiences in workplace safety from various industries. This opening dialogue laid a great foundation for an open and constructive exchange of ideas throughout the afternoon.

Teknikum’s safety culture in focus

During the main session, Tero Suominen, Teknikum’s Safety Manager, and Esko Mäntyharju, QEHS Director, presented the company’s safety management system, practical solutions, and approach to continuous improvement. They explained how safety is implemented on the shop floor and supported across the organization.

Key topics discussed included:

-

Systematic risk assessment and prevention

-

Employee involvement in safety observations and initiatives

-

The role of leadership and supervisors in developing safety culture

-

Cooperation with occupational health services and authorities

Safety in practice – plant tour

The session concluded with a guided tour of the production facilities. During the walk-through, visitors observed Teknikum’s safety practices in action and had the opportunity to make their own safety observations and share improvement suggestions. This hands-on experience brought valuable context to the earlier discussions and highlighted how safety is woven into everyday work.

Continuous improvement through collaboration

Safety is one of Teknikum’s core values.Our goal is to constantly improve – not only to prevent accidents but to ensure a healthy, motivated, and engaged workforce. Being part of the Nolla Tapaturmaa Forum supports this mission by enabling knowledge sharing and mutual learning across industries.

A warm thank you to all the visitors for your presence, inspiring conversations, and shared commitment to workplace safety. Together, we take meaningful steps – toward zero.

March 13, 2025 -Finland

At Teknikum, we are committed to pioneering sustainable polymer technologies. That’s why we are excited to participate in Bioboost, a joint research project, withour own Business Finland-funded subproject.

As part of Bioboost, Teknikum will share our expertise in rubber materials, collaborate with industry partners, and test new bio-based raw materials developed during the project. Our goal is to explore lignin-based alternatives and evaluate their performance compared to conventional ingredients such as carbon black and traditional antioxidants.

Key focus areas of our research:

-

Studying lignin-based materials from different sources in various rubber compounds.

-

Comparing their properties to conventional and other sustainable raw materials.

-

Identifying the most suitable lignin types for rubber applications.

Commitment to climate goals & SBTi targets

Teknikum’s participation in Bioboost aligns with our Science Based Targets initiative (SBTi) commitments, where we strive to reduce our environmental impact by innovating with more sustainable raw materials. By investigating lignin’s potential in rubber applications, we aim to move closer to a low-carbon, circular economy while maintaining the high-performance standards our customers expect.

Innovation for a Greener Future

We believe that by replacing fossil-based raw materials with sustainable alternatives, we can help shape a more eco-friendly and responsible future for the rubber and polymer industry. 💚 Together, let’s boost bio-based innovation!

Learn more: Teknikum Sustainability Initiatives

Teknikum – A pioneer in sustainable polymer technology

Teknikum provides industrial customers with high-performance rubber, plastic, silicone, and foam solutions, including industrial hoses, molded products, and mill lining services. With factories and offices in Finland, Hungary, and Germany, Teknikum operates under three core values:

Safety | Sustainability | Sincerity

February 11, 2025 – Finland

Teknikum, a Finnish leader in polymer technology and a pioneer in sustainable solutions, continues to make significant progress in reducing emissions and improving environmental responsibility. Since committing to the Science Based Targets initiative (SBTi) in 2021, Teknikum has set clear climate goals aligned with the 1.5°C emission scenario.

The 2024 results highlight Teknikum’s strong progress toward its 2030 SBTi targets, with significant emission reductions across all scopes.

Measurable emission reductions in Scope 1 & 2

-29% reduction in Scope 1 & 2 emissions from 2020 baseline

Teknikum has reduced its direct and indirect greenhouse gas emissions (GHG) by 29% since 2020, moving steadily toward its goal of a 50% reduction by 2030. This achievement was made possible by:

- Energy efficiency improvements in production facilities

- Transitioning to renewable energy sources

- Installing energy-efficient lighting and insulation

- Upgrading equipment to reduce self-generated energy use

“Our energy-saving initiatives have delivered concrete results. By optimizing production processes, investing in more efficient machinery, and increasing the use of renewable energy, we have significantly reduced emissions,” says Esko Mäntyharju, Director of HSQE at Teknikum Group.

Scope 3 Emission Reductions Through Sustainable Products & Processes

-54% reduction in Scope 3 emissions from 2020 baseline

Scope 3 emissions, primarily generated from purchased goods, services, and capital goods, remain a key area of focus. Teknikum is driving innovation by incorporating:

- Recycled and bio-based raw materials into its products

- TEKNICROSS® railway rubber level crossing elements, made from recycled rubber

- Industrial hoses produced partially with recycled or bio-based rubber

Sustainability is embedded in Teknikum’s production process, with a strong focus on material efficiency, waste reduction, and recycling at all facilities. Teknikum’s environmental management is certified under ISO 14001 across all locations.

Strengthening supplier responsibility & compliance

Enhanced supplier Code of Conduct

Teknikum has reinforced its sustainability commitments with the Supplier Code of Conduct, requiring all suppliers to comply tight ESG (Environmental, Social, and Governance) standards. Teknikum works closely together with its suppliers to ensure ESG adherence and encourage improvements.

“Collaboration with our suppliers plays a crucial role in achieving emission reductions in our supply chain. By strengthening our sustainability policies, we drive positive change throughout our value chain,” comments Mäntyharju.

The roadmap to 2030: What’s next?

Future focus areas for sustainability progress

With a clear SBTi roadmap, Teknikum is committed to further emission reductions through:

- Exploring new energy sources for production

- Increasing heat recovery and reducing energy consumption

- Increasing production efficiency with layout changes and production method development

- Developing innovative, low-carbon products for customers

Reducing emissions is not just about what we do internally. It’s also about developing innovative, more sustainable solutions that support our customers in reaching their environmental goals,” says Mäntyharju.

Committed to Transparent Sustainability Reporting

Teknikum Group will continue reporting on its sustainability progress annually across its communication channels, ensuring transparency and accountability in achieving the 2030 SBTi goals.

Learn more: Teknikum Sustainability Initiatives

Teknikum – A pioneer in sustainable polymer technology

Teknikum provides industrial customers with high-performance rubber, plastic, silicone, and foam solutions, including industrial hoses, molded products, and mill lining services. With factories and offices in Finland, Hungary, and Germany, Teknikum operates under three core values:

Safety | Sustainability | Sincerity

Contact

12. December 2024

This week, Teknikum had the privilege of hosting great visitors, including the Minister of Employment of Finland, Arto Satonen, and the CEO of Sanok Rubber Company, Piotr Szamburski, along with representatives from the City of Sastamala including Mikko Rauva, Business Specialist, and Tanja Aarnikuru, Director of Economic Development. Teknikum Group’s CEO, Jani Hämäläinen, warmly welcomed the visitors.

The visit offered an excellent opportunity to showcase Teknikum’s expertise in polymer technology, share insights on the latest industry trends, and strengthen relationships that drive the growth of both our business and the local community. Conversations during the visit focused on sustainability and innovation, emphasizing Teknikum’s commitment to delivering advanced, environmentally friendly solutions for demanding industrial applications.

Teknikum continues to lead the way in polymer technology, offering a broad range of products and services, including industrial hoses, wear-resistant linings, and tailored technical solutions designed to meet diverse customer needs. Visits like this reaffirm our dedication to fostering collaboration and driving positive change within the industry.

We extend our heartfelt thanks to our guests for their time, insightful discussions, and shared vision for innovation and sustainability. Together, we look forward to continuing our journey of growth and excellence.

In the photo, from left to right, you can see Mikko Rauva, Piotr Szamburski, Arto Satonen, Tanja Aarnikuru, and Jani Hämäläinen.

May 6, 2024 – Sastamala, Finland

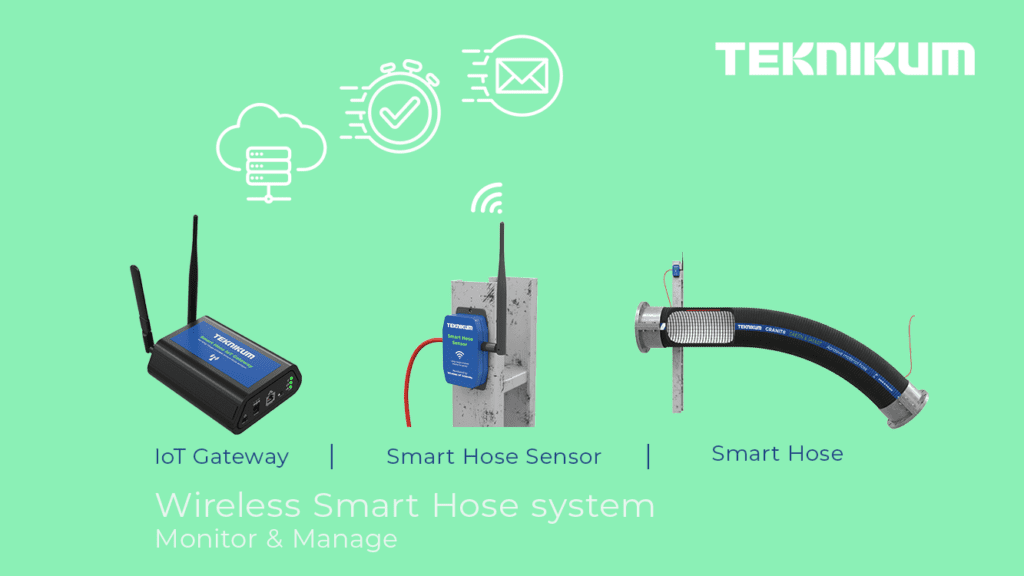

In spring 2024, Teknikum brings forth an upgraded wireless solution for wear monitoring of abrasive smart hoses. To enable even more maintenance cost savings and as easy lifecycle management as possible, the system is now built around a Wireless IoT Gateway that is able to monitor up to 20 smart hoses at once. When multiple IoT Gateways are installed, the coverage can include hundreds of hoses and bends.

Customer’s piloting the system have been very pleased to receive feedback on their hoses durability without the need to make a maintenance stop and a visual check. But how is it done today?

When a Smart hose’s lining reaches a specific point of wear, the Wireless Smart hose sensor sends an alert to the IoT Gateway, and all the way to Teknikum’s secure Cloud-based monitoring system. The alert point is within the rubber lining layers and by calculating the use life to the point of alert, it’s possible to estimate exact life of the hose until the point of wearing out.

The alert point gives typically more reaction time with rubber hoses, but with CERAMIC lining and highly abrasive materials, the reaction time can be few days – and thus the information is critical. Teknikum’s CERAMIC lining itself allows 3-10 times longer life than a rubber hose or a steel pipe. When this long life solutions is combined with the Wireless Smart Hose system, industrial plants in Mining and Energy sector can operate on high performance risk-free.

“We are very excited to launch this new system and believe that it will solve critical operational issues and make plant management easier for our customers”, says Mr. Timo Kokkonen, Director of Teknikum Hoses BU.

We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach.

A significant part of the added value is the continuous development of materials in-house.

– Timo Kokkonen, Director, Hoses BU

Bringing added value to various harsh operational environments

This new wireless monitoring system is especially designed for environments, where abrasive hoses are used. This includes Energy, Mining and other heavy industries. Some examples of the use cases are transfer of sand, rocks, minerals and granulates.

The most critical place for the abrasive material handling is an outer curve of a hose. Teknikum’s new Smart Hose monitoring solution offers various technical structures for it: according to customers’ needs, the monitoring cable can be built within one or two rubber layers and distributed even to various sectors. This allows the process owner to manage efficiently over the hoses’ life cycle – in some cases straight hoses it can be even turned 3 times during their use, to get most out of the inner lining.

Secure cloud-based monitoring enables fast off-site alerts and advanced material development

In the core of Teknikum’s IoT solution is its new cloud-based monitoring software. When data is received from site via the sensors and IoT Gateway, it’s processed withing the monitoring system. The alert points are defined together with the customer and when triggered, the system sends an alert to the customer. In addition, the system collects important wear monitoring data from the hose’s lining that allows continuous in-house material and product development for the customer’s operation environment.

“We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach. A significant part of the added value is the continuous development of materials in-house”, says Mr. Kokkonen.

» Teknikum is launching the new system at EuroMine expo, Skellefteå, SWEDEN 28 – 30 May 2024. Visit our team at booth #208 in Copper Hall and check out our Wireless Smart Hose system demo!

Contact us to learn more

Heavy process industry and mining industry

Jani Lampinen

Sales Manager, Industrial hoses BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 411 7810

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263