One-stop-shop for custom polymer products

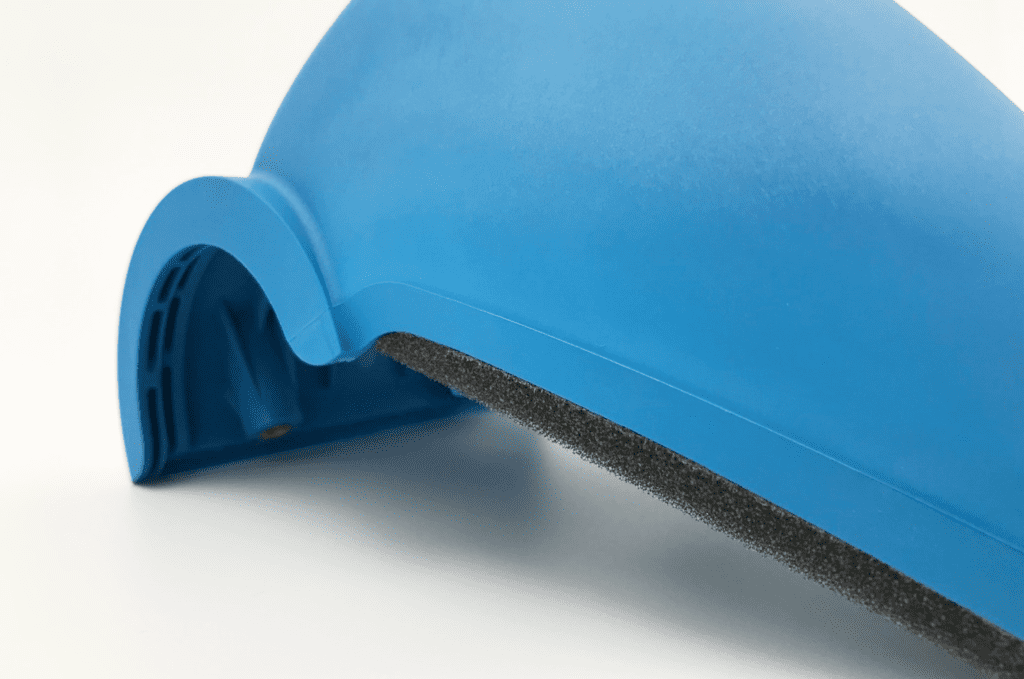

Teknikum combines different polymers, such as foam, plastic and rubber, into one product according to customer’s requirements.

Teknikum is an expert in technical foam converting and plastic parts manufacturing. Teknikum Group has five factories, which are located in Hungary and Finland. The company differentiates from competitors by combining materials to more complex end-products like helmets and half masks. When needed, Teknikum delivers finished assembled products, taking care of the whole manufacturing process. Contract manufacturing projects are done for several international brands operating in personal protective equipment, electronics, machine building, automotive and home appliances industries.

Teknikum Group’s Foam BU Director Mr. Cebastian Doepel is continuously impressed by the efficiency and know-how of his team. The state-of-the-art automated foam and plastic machinery is completed with experienced project team, R&D department and of course the factory workers.

“We have a unique set of skills to serve our customers”, Mr. Doepel says. “From the raw material sourcing to efficient prototype simulation and mass production, Teknikum is one-stop-shop for the customer – whether they are in the product development phase or established in their market”, Mr. Doepel tells.

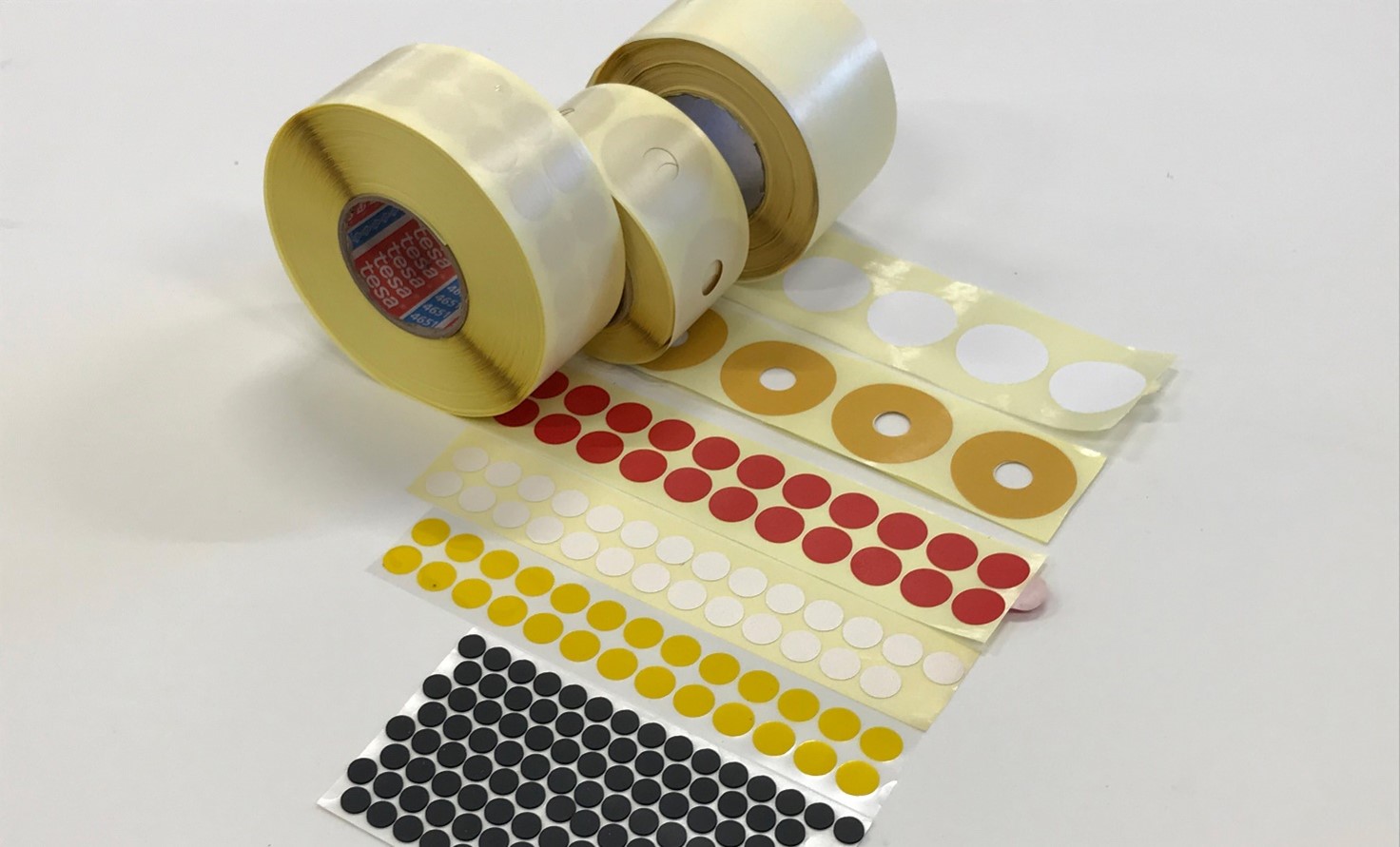

Typical products for Automotive Industry include different kind of kiss-cut foam and plastic tapes.

Agile partner with know-how

Along with foam converting and moulded product, Teknikum manufactures industrial hoses in Hungary and Finland, has sales office in Germany and wide reseller network in Europe.

The versatile manufacturing experience gives several benefits to demanding customers. The company differentiates from competition by combining plastic parts with foam and rubber and being able to deliver finished assembled products.

“Teknikum’s product development department serves with latest technologies: agile 3D modeling is available with CAD and 3D-printing. Also, both FEM and Moldflow analysis are used for evaluating functionality and durability of the product, ensuring quality finish”, tells Mr. Doepel.

“We have a unique set of skills to serve our customers”, Mr. Doepel says.

“From the raw material sourcing to prototype simulation and mass production, Teknikum is one-stop-shop for the customer – whether they are in the prototype phase or established in their market”.

Simple or complex quality products

Sales Manager Mr. Ádám Boldizsár helps customers with the team to find suitable solution, from early engineering stage to mold deliveries and eventually to a product delivery.

“By using the injection molding, extrusion and 2D/3D cutting techniques, our plastic department manufactures customer-specific special products. Our raw material selection covers all the main grades of thermoplastics, and certain engineering plastics such as POM, PA, and PA-fiberglass compounds. Additionally, our high-tech mold shop manufactures and maintains molds for customer’s projects”, Mr. Boldizsár tells.

Teknikum’s high-tech mold shop manufactures and maintains molds for customer’s projects.

“Some of our products may be very small in size, but here in Jászladány our equipment also enables making very large plastic products with up to 2,000 cubic centimeters in volume with a maximum weight of 4 kg”, Mr. Boldizsár tells.

“With technical foam, we offer wide range of materials, such as light PU, waterproof PE, chemical resistant EPDM, recycled rebound foams and special materials and tapes”, Mr. Boldizsár explains.

Typical volume foam products are done by using kiss-cut or full-cut technologies.

Teknikum Kft. has been operating in Jászladány, Hungary, since 1993. The foam plant offers state-of-the art automated machinery for demanding contract manufacturing.

Sustainability is one of the group’s operational values

Teknikum is committed to Paris agreement via Science Based Target initiative. This ensures that customers can rely on Teknikum’s future-proof sustainable quality, along with ISO and IATF certified production.

“Customers select us, when they are looking for high-quality production with overall cost-efficiency and easy project management”, Mr. Boldizsár says.

“We offer the best of Hungarian manufacturing, combined with Finnish know-how”, Mr. Boldizsár concludes.

Recycled foam allows many benefits when customers can select wanted foam mix features.

Contact us

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263Industrial customers, Moulded products

Satu Hyökki-Siltanen

Sales Manager, Moulded products BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 468 1181

Ilkka Nieminen

Director, Plastics Business Unit

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 40 5101 868

Cebastian Doepel

Director, Business Development and Foam & Compounds BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 386 0027