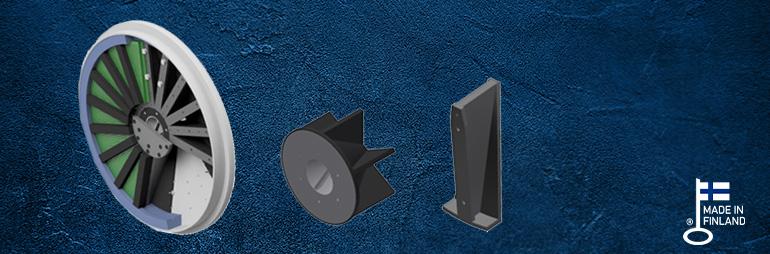

Teknikum® Rubber Pulp Discharging Systems

Application

Teknikum® Rubber Pulp Discharging Systems provide longer lifetime for grate discharge mill liners in a specific condition: wear resistant rubber and steel frame body creates combination, which is especially good in circumstances where pulp lifters must endure high pulp flow and abrasive wear from grinded mineral.

All Teknikum® Rubber Pulp Discharging System liner components are moulded or rubber coated and tailor made for the customer mills and processes.

The quality and thickness of rubber on components will be chosen for every purpose differently. Rubber and shape must be chosen according to grinding and process parameter and throughput needs.

Advantages

- Good wear resistance

- Good corrosion resistance

- Easy installation

- Light weight

Download datasheet