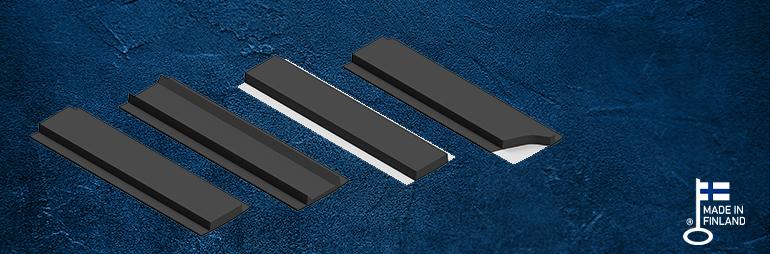

Teknikum® Rubber Shell Plates

Application

Teknikum® Rubber shell plates are manufactured from wear resistant TRL rubber material and can also be equipped with steel background to give additional strength to the structure.

The thickness of the shell plates is selected in order to increase life of linings. Also, increasing of mill capacity can be taken account. The width of shell plate is designed for optimum protection from the lifter bars. The quality of rubber and shape of shell plate will be chosen for every purpose differently from Teknikum® TRL mill lining rubbers. Rubber and thickness must be chosen according to grinding and process parameter.

All rubber shell plates are moulded and tailor made for the customer mills and processes.

Versions

- VL – all rubber shell plate made from wear resistant rubber.

- VLS – steel backed shell plate with wear resistant rubber on at wearing surface.

- VLT – steel backed shell plate with steel/rubber wings fully encapsulated steel back with with wear resistant rubber on wearing surface. The capsulated steel backing is well protected against chemical corrosion.

- VLA – shell plate for wave linings is specially designed for rubber wave lining type.

Advantages

- Good wear impact wear resistance

- Good wear abrasive wear resistance

- Increasing of mill capacity

- Easy installation

- Light weight

- Low noise level vs. steel liners