New Wireless Smart Hose system allows to manage all abrasive hoses on-site

May 6, 2024 – Sastamala, Finland

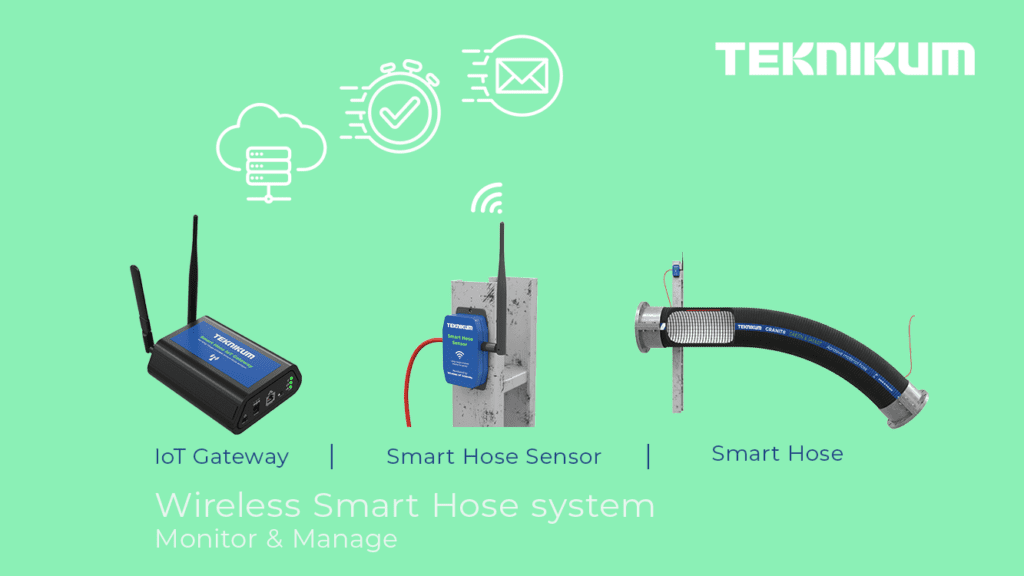

In spring 2024, Teknikum brings forth an upgraded wireless solution for wear monitoring of abrasive smart hoses. To enable even more maintenance cost savings and as easy lifecycle management as possible, the system is now built around a Wireless IoT Gateway that is able to monitor up to 20 smart hoses at once. When multiple IoT Gateways are installed, the coverage can include hundreds of hoses and bends.

Customer’s piloting the system have been very pleased to receive feedback on their hoses durability without the need to make a maintenance stop and a visual check. But how is it done today?

When a Smart hose’s lining reaches a specific point of wear, the Wireless Smart hose sensor sends an alert to the IoT Gateway, and all the way to Teknikum’s secure Cloud-based monitoring system. The alert point is within the rubber lining layers and by calculating the use life to the point of alert, it’s possible to estimate exact life of the hose until the point of wearing out.

The alert point gives typically more reaction time with rubber hoses, but with CERAMIC lining and highly abrasive materials, the reaction time can be few days – and thus the information is critical. Teknikum’s CERAMIC lining itself allows 3-10 times longer life than a rubber hose or a steel pipe. When this long life solutions is combined with the Wireless Smart Hose system, industrial plants in Mining and Energy sector can operate on high performance risk-free.

“We are very excited to launch this new system and believe that it will solve critical operational issues and make plant management easier for our customers”, says Mr. Timo Kokkonen, Director of Teknikum Hoses BU.

We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach.

A significant part of the added value is the continuous development of materials in-house.

– Timo Kokkonen, Director, Hoses BU

Bringing added value to various harsh operational environments

This new wireless monitoring system is especially designed for environments, where abrasive hoses are used. This includes Energy, Mining and other heavy industries. Some examples of the use cases are transfer of sand, rocks, minerals and granulates.

The most critical place for the abrasive material handling is an outer curve of a hose. Teknikum’s new Smart Hose monitoring solution offers various technical structures for it: according to customers’ needs, the monitoring cable can be built within one or two rubber layers and distributed even to various sectors. This allows the process owner to manage efficiently over the hoses’ life cycle – in some cases straight hoses it can be even turned 3 times during their use, to get most out of the inner lining.

Secure cloud-based monitoring enables fast off-site alerts and advanced material development

In the core of Teknikum’s IoT solution is its new cloud-based monitoring software. When data is received from site via the sensors and IoT Gateway, it’s processed withing the monitoring system. The alert points are defined together with the customer and when triggered, the system sends an alert to the customer. In addition, the system collects important wear monitoring data from the hose’s lining that allows continuous in-house material and product development for the customer’s operation environment.

“We don’t just move material from one maintenance stop to the next but help save the environment and customer costs in the long run by continuously developing our offering on a location-based approach. A significant part of the added value is the continuous development of materials in-house”, says Mr. Kokkonen.

» Teknikum is launching the new system at EuroMine expo, Skellefteå, SWEDEN 28 – 30 May 2024. Visit our team at booth #208 in Copper Hall and check out our Wireless Smart Hose system demo!

Contact us to learn more

Heavy process industry and mining industry

Jani Lampinen

Sales Manager, Industrial hoses BU

Teknikum Group Ltd

firstname.lastname@teknikum.com

+358 50 411 7810

Christian Körber

Sales Manager, Central Europe

Teknikum GmbH

christian.koerber@teknikum.com

+49 162 1855263